Heat Transfer Fluids

Various industrial and commercial heat transfer systems operate at temperatures outside the normal freezing and boiling points (of water). In order to protect heat transfer systems from freezing, bursting or boiling, a propylene glycol water mixture is used in secondary loop systems. In the case of cooling systems the heat transfer fluid is used to reduce the freezing point below operational temperatures, whereas the heat transfer fluid is used to increase the boiling temperatures in alternative applications.

Bracton Long Life Heat Transfer Fluid

Not all Propylene Glycol is the same, BractonSafe Long Life Propylene Glycol is a specifically formulated heat transfer liquid with built in inhibitors to assist in the prevention of corrosion and fungus growth in heat transfer systems. BractonSafe Long Life Propylene Glycol is an odourless liquid, recognised as safe for use in food & industrial applications by the relevant US and Australian authorities. Bracton offers two types of Propylene Glycol; BractonSafe Long Life Heat Transfer Fluid and Standard USP Grade.

BRACTON LONG LIFE HEAT TRANSFER FLUID (USP GRADE PROPYLENE GLYCOL WITH INHIBITORS)

BractonSafe Long Life Propylene Glycol with Inhibitors is formulated with USP Grade PG and has five times the normal life span of standard USP Grade Propylene glycol. Bractons’ special formulation reduces wear on heat transfer systems, ensuring equipment remains hygienic and corrosion free for longer, protecting plant equipment against excessive wear. Bracton Long Life Glycol is manufactured with USP grade propylene glycol and FDA approved inhibitors.

The product has been in use in the hospitality and food processing industries for the past 15 years. Bracton Long Life Glycol as recent under gone testing at a NATA lab for the following to confirm anti-corrosive capabilities; ASTM D1384, ASTM D6130, ASTM D5827, ASTM D6130, ASTM D5827, OL1029, OL1034, ASTM D1287, OL1003 & ASTM D1121. Shelf life of sealed, unused Bracton Long Life Glycol is five years from date of manufacture. Monthly or quarterly checks of pH and concentration by refractive index are recommended, ask about our in-house analysis options.

BRACTON PROPYLENE GLYCOL USP STANDARD

BractonSafe propylene glycol USP is a high purity product, which meets the requirements of the current United States and European Pharmacopeias and various other regulations and standards for pharmaceutical, food and cosmetic additives. As a result of its low vapour pressure, low toxicity, low flammability and high purity, propylene gycol USP is cleared for use in the United States in accordance with U.S. FDA requirements. Bracton Glycol is cleared for indirect food contact: 21 CFR 175.105, 21 CFR 175.300, 21 CFR 175.320, 21 CFR 176.170, 21 CFR 176.210, 21 CFR 177.1680, 40 CFR 180.1001(c) (e) & 40 CFR 182.99.

BractonSafe Long Life Heat Transfer Fluid is also known as;

- BractonSafe Propylene Glycol with Inhibitors

- Inhibited Propylene Glycol

- PG with Inhibitor – PGUSP

- Long Life Propylene Glycol

- Secondary heat transfer fluid BractonSafe Long Life Propylene Glycol is a economical alternative to Dow’s Dowfrost(TM) Product Line.

NOTE: BractonSafe can supply bulk ethylene glycol and technical grade propylene glycol on request, these products are not suitable for direct or indirect food applications.

BractonSafe Long Life Propylene Glycol with corrosion protection

3 x 5 Kg Carton

25 Kg Drum

215 Kg Drum

1000 Kg IBC (Tote)

Nb: BractonSafe Long Life Propylene Glycol with corrosion protection is also available in pre diluted, ready to use concentrations. Ideal for new installations.

BractonSafe Propylene Glycol USP Grade Standard

215 Kg Drum

1000 Kg IBC (Tote)

Bracton Preservative (Glycol Corrosion Inhibitor)

12x500mL Carton

3 x 5L Carton

25L Drum

215L Drum

Bracton Distilled Water

25L Drum

215LDrum

1000L IBC (Tote)

TECHNICAL GUIDANCE

Can standard Propylene Glycol be Inhibited or converted to Long Life Glycol?

Yes, with BRACTON PROPYLENE GLYCOL PRESERVATIVE (GLYCOL CORROSION INHIBITOR)

Propylene Glycol is an excellent heat transfer liquid with low toxicity, suitable for food grade applications such as beverage cooling and food processing. One drawback is that Propylene Glycol has an average shelf life of twelve months from date of manufacture, when stored in accordance with PG manufacturers guidelines (below 40C and away from UV light sources).

Given that Propylene Glycol is for the most part imported into Australia, the actual shelf life is closer to 8 – 10 months by the time glycol enters into operation. As Propylene Glycol is exposed to operational environments including elevated temperatures and oxidisation, Propylene Glycol fluid reacts becoming acidic, in turn increasing the wear on equipment and higher maintenance costs. Fortunately, The chemists at Bracton have developed an easy to use food grade additive, designed to preserve the shelf life of USP grade propylene glycol by up to five times in normal conditions.

Bracton Propylene Glycol Preservative is made with food grade FDA approved materials and has been employed to protect food processing systems of some the worlds largest multi-national food manufacturers, breweries, hotels and industrial manufacturers. Bracton Propylene Glycol Preservative serves as the front line defence, protecting against systems against acidity, corrosion while inhibiting mould and fungus growth.By choosing to use Bracton Propylene Glycol Preservative in heat transfer applications, your company will save in replacement and maintenance costs.

Ideal for use:

- Commercial & Domestic Draught Beer Systems

- Food Processing systems

- Dairy, Seafood and Wine production systems

- Any commercial or industrial system that requires glycol use.

Bracton Propylene Glycol Preservative Characteristics:

- Prevents corrosion

- Prevents bacterial build up

- Prevents circulation blockage

- Extends the life of Propylene Glycol

- Increases efficiency in systems

Use: Bracton Propylene Glycol Preservative 10Lt treats 200Kg of pure propylene glycol (UNDILUTED).

NOTE: Bracton Propylene Glycol Preservative is also known as Propylene Glycol Inhibitor.

Where can Propylene Glycol be used?

- Propylene Glycol Applications Coolant, anti freeze, heat transfer, thermal transfer in secondary heat transfer systems.

- Beverage and beer cooling systems

- As a less toxic antifreeze in solar water heating systems

- To regulate humidity.

Why should ethylene glycol not be used in food applications?

Risks – Because secondary refrigerant is pumped around a beer system with flooded fonts, there is a slight chance there may be cross contamination. Therefore the refrigerant MUST be non-toxic.

Toxicity – Ethylene glycol poisoning is caused by the ingestion of ethylene glycol (the primary ingredient in both automotive antifreeze and hydraulic brake fluid). It is a toxic, colourless, odourless, almost non-volatile liquid with a sweet taste and is occasionally consumed by children for its sweetness. Following ingestion the symptoms of poisoning follow a three-step progression starting with intoxication and vomiting, before causing metabolic acidosis, cardiovascular dysfunction, and finally acute kidney failure. The major cause of toxicity is not the ethylene glycol itself but its metabolites. Propylene Glycol The acute oral toxicity of propylene glycol is very low, and large quantities are required to cause perceptible health damage in humans.

Identification:

a. Raw Ethylene Glycol –Can be colourless or fluorescent green depending on supplier

b. Raw Propylene Glycol – Colourless

c. BractonSafe Long Life Propylene Glycol – Translucent Pink

What does freeze & burst protection mean?

Freeze protection is necessary if a cooling system is going to be actively pumping fluid at the lowest operational temperature where there is no room in the system for expansion to accommodate a slush formation. To obtain adequate freeze protection, the glycol solution must maintain a freezing point at least 3 degrees Celsius lower than operational temperature. Frequent scheduled system checks are recommended to ensure the propylene glycol water mixture is not diluted beyond the required operational ratios.

Burst protection is required if the system will sit dormant at temperatures below the freezing point of the fluid and there is adequate space to accommodate the expansion of the ice/slush mixture while the system is inactive. For these situations, the system needs enough glycol to keep the fluid from freezing solid. As the temperature drops below the freezing point, ice crystals begin to form. Because water in the solution freezes first, the remaining glycol solution becomes concentrated. This results in a flowable slush of ice crystals and glycol.

Bracton manufactures a Long Life Propylene Glycol which has a low toxicity level and can be used in equipment that has contact with food and beverage products. Including beverage cooling, food processing, secondary cooling and heating agents, dehumidifying and defrosting.

Why use distilled water when diluting Heat Transfer Fluids?

Tap water quality varies significantly from location to location. The impurities and minerals found in tap water while general not harmful to one’s health, can be detrimental to heat transfer systems, increasing the risk of unscheduled system down time and reducing system life span. Hard water causes scale build up, where salts cause corrosion to systems. Therefore heat transfer fluids are preferably diluted with distilled or deionised water.

- Chlorides < 25ppm

- Sulfates < 25ppm

- Total hardness as Calcium Carbonate (CaCO3) < 100ppm

Definition: Hard water is water that has high mineral content. Hard water can pose serious problems in industrial and commercial equipment, where water hardness is monitored to avoid costly breakdowns in boilers, cooling equipment, and other equipment that handles water.

Analysis of water hardness in major Australian cities by the Australian Water Association [AWA] shows a range from very soft (Melbourne) to very hard (Adelaide). Average Reported Hardness levels of Calcium Carbonate (CaCO3) in ppm are:

- Canberra: 40

- Melbourne: 10 – 26

- Sydney: 39 – 60

- Perth: 29 – 226

- Brisbane: 100

- Adelaide: 134 – 148

- Hobart: 6 – 34

- Darwin: 31

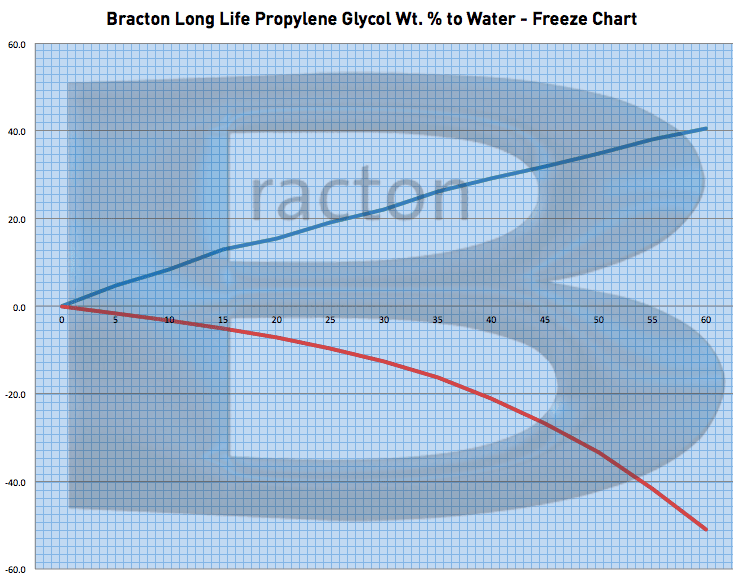

Propylene Glycol dilution guidance

- Identify equipment operational temperature range.

- Read graph to identify desired Bracton Propylene Glycol mixing ratio.

- To a clean head transfer system add the right amount of Bracton Propylene Glycol.

- Top up with distilled or deionised water and agitate water.

- Check solution concentration with a refractometer to ensure desired operating parameters.

NOTE: Bracton recommends a minimum dilution 25% to maintain system corrosion and fungus protection.

Can Bracton analyse our heat transfer fluid?

Yes, contact your local Bracton distributor today and ask for a Bracton heat transfer fluid check kit. Bracton will analyse the sample and provide a report and recommendation to ensure your fluid is operating to specification.

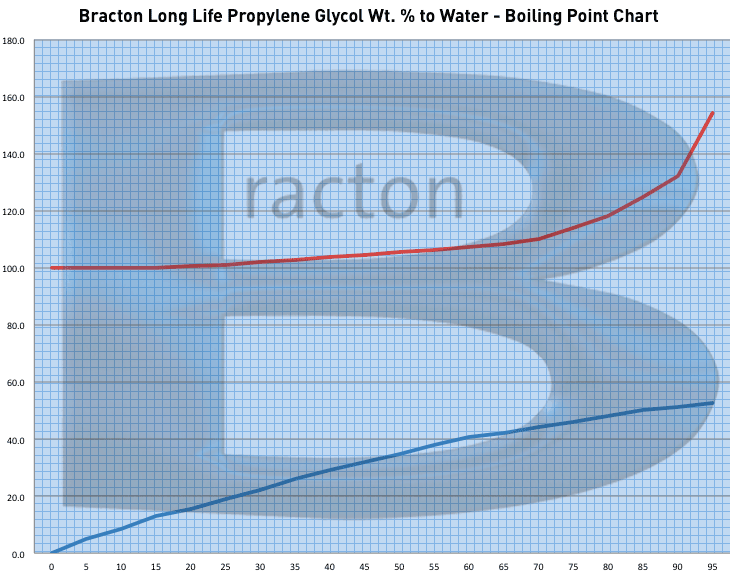

How much water should be added to reach the correct freeze or boiling point?

RED LINE: Relative Freeze Point°C

BLUE LINE: Relative Refractometer Reading °Bx

CENTRE LINE : Propylene Glycol Concentration

RED LINE: Relative Boiling Point°C

BLUE LINE: Relative Refractometer Reading °Bx

CENTRE LINE : Propylene Glycol Concentration