Beerline Cleaners

Bracton beer line cleaners are used in 7 out of 10 hotels across Australia. Approved by all major and local breweries in Australia, Europe and USA.

Weekly beer line cleaning is part of the essential process for fresh and crisp tasting beer. When used correctly, Bracton Beerline Cleaners ensure a total clean, meaning all beer stone and bacteria build-up is completely removed from beer lines, FOB detectors, beverage heat exchangers and font riser lines. Bracton Beerline Cleaners are approved and often recommended by major brewery technicians to guarantee the beer tastes as it should, so you can serve the best possible beer.

The four key components to the beer line cleaning process that determine the level of hygiene achieved as specified by the major breweries:

- Chemical Contact Time with Beer Lines – Laboratory research indicates beerline cleaning should be conducted for a minimum of two hours. deviation from this minimum contact time, may cause inconsistent results.

- Frequency of Beer Line Cleans – Beer lines should be carried out once a week to ensure clean beer lines, this is paramount for warmer regions.

- Chemical Used – There are a variety of beer line cleaners on the market, for best results every time we recommend the use of Bracton DP1 & DP2 two part beerline cleaner. The Bracton DP1 & DP2 two part beer line cleaning process has consistently outperformed the alternatives for over thirty five years, majority of Australian Hotels & Clubs cannot be wrong! Bracton DP2 provides superior bacteria kill rate and sanitation over single part cleaners. In areas where a single part beerline cleaner is preferred use Bracton Twin.

NOTE: Both Bracton beerline cleaning processes are brewery approved for weekly cleaning and it is unnecessary to switch between beerline cleaners, for more information contact Bracton or your local draught beer technician. - Type of beer – Each type of beer is formulated differently and therefore some beers cause greater build up in beer lines than others. A weekly beer line clean ensures consistency across all beer types.

BRACTONSAFE CRAFT BEER LINE CLEANER (Non-Hazardous)

Brewery approved BractonSafe Craft Beer Line Cleaner is formulated using the latest in surface active technology.

This product is non-hazardous making the workplace safer and eliminating the need for storage of caustics.

BractonSafe Craft Beer Line Cleaner has proven to deliver improved head retention and beer presentation leading to increased beer sales.

BSSAFESET3 Full Safety Kit

- non-vented goggles

- gloves

- mask

- apron

- test strips

- signage

BSAFESET2

Full safety kit excluding apron.

BSAFESET

Non-vented goggles and gloves.

DP1 / DP2 DETERGENTTWO PART BEER LINE CLEANERS

Bracton DP1 & DP2 Brewery Approved Beerline Cleaner is Australian Hotel & Clubs preferred beer line cleaner.

Available in a range of sizes to suit your venue. Bracton DP1 & DP2 can be used for beer line recovery cleans, contact your draught beer technician or Bracton for more information on performing a line recovery clean.

Product Data Sheet – Bracton DP1 Beer Line Cleaner

Product Data Sheet – Bracton DP2 Beer Line Cleaner

Bracton DP1 Beer Line Cleaners

3x5L Carton

15L Drum

24L Drum

Bracton DP2 Beer Line Cleaners

3x5L Carton

15L Drum

24L Drum

Bracton DP1 & DP2 Kits

10L Set (2 x 5L)

10L Handypack Set (10 x 1L)

20L Set (4 x 5L)

TWIN DETERGENTONE PART BEER LINE CLEANER

Bracton Twin Brewery Approved Single Part Beerline Cleaner suitable for use in colder regions with low levels of beer line build up.

Bracton Twin

10L Set (10x1L)

15L Drum

BRACTON DOSATRON AUTOMATICBEER LINE CLEANING SYSTEM

The Bracton Beer Line Mixing System is the industry standard in safety and efficiency in beer line cleaning. When connected to water supply, the dispenser operates without electricity, using water pressure as the power source. As water flows through, it activates the dispenser drawing the correct mixture of DP1 and DP2 cleaning solution (accurate to 0.1%) into the beer lines and towards the beer taps.

The Bracton Beer Line Mixing System increases efficiency by mixing the correct amount of cleaning solution (no wastage) and reducing labour requirements (no setup time). This enhances safety precautions by eliminating a staff contact point with chemicals and pressurised vessels.

Bracton Dual Mixing System

Suitable for use with Bracton DP1 & DP2 Beerline Cleaner

Bracton Single Mixing System

Suitable for use with Bracton TWIN Beerline Cleaner

INDICATOR TEST PAPERS FOR BEER LINE CLEANERS

Bracton Test Papers – A simple method of testing when Beerline Cleaner is present. Paper turns blue in alkaline solutions, a must for safety.

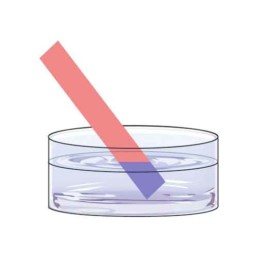

USAGE: After performing normal brewery cleaning process and flushing, test for alkalinity by taking a pink test paper and wetting it with beerline flush water from tap. If it changes to a bluish colour, then continue flushing with water and retest until paper stays pink. Pink colour on the testing paper means it is safe to remove signs.

Bracton Test Papers

200 Strip Pack

BEER LINE CLEANING SAFETY EQUIPMENT

Meet your health and safety requirements with a Bracton Personal Protective Equipment (PPE) Safety Kit containing suitable PVC gloves and goggles for manual handling of any hazardous chemicals.

BSSAFESET3 Full Safety Kit

- non-vented goggles

- gloves

- mask

- apron

- test strips

- signage

BSAFESET2

Full safety kit excluding apron.

BSAFESET

Non-vented goggles and gloves.