Beer FOBs + manifolds

Beer FOBs and manifolds

Bracton manufactures a full range of Beer FOBs, Manifolds and Beer pumps. For beer system and venue specifications contact an Bracton beer equipment specialist.

BRACTON FOB DETECTORS

A Foam on Beer Detectors (FOBs) is used on long draught beer lines to minimise beer wastage. Beer FOBs are installed in the cool room on the tapping board and contain a float which drops when the keg is empty, keeping the beer line charged with beer (rather than foam).

Precision manufactured Bracton Beer FOB detectors have a flow rate in Australia at over 24 litres per minute making them ideal for medium to high volume applications i.e. Hotels, clubs and stadiums. Increased flow rate is essential to avoid float release in periods of high demand. With over 15,000 Bracton FOB detectors in the market, you cannot go wrong.

Bracton Foam on Beer Detectors (FOBs) are available with a wide range of inlets and outlets to suit all cellar board installation templates.

FOB INLET OPTIONS

- FDBARB6/I FOB Inlet Barb / S/S 6mm

- FDBARB8/I FOB Inlet Barb / S/S 8mm

- FDBARB10/I FOB Inlet Barb / S/S 10mm

- FDBARB12/I FOB Inlet Barb / S/S 12mm

- FDMBL/I FOB B-Lock Inlet // Connects to 3/4″ B-Lock adaptor

- FDBARBG56 FOB Inlet Barb /G56 Beer pump // Connects a beer pump direct to FOB inlet, tool-less install hygienic design

- FDBARBG56DUAL FOB Dual G56 Pump Manifold w/JG FOB Adaptor // Connects 2 x beer pumps direct to FOB inlet, for high volume applications tool-less install hygienic design

FOB OUTLET OPTIONS

- FDBARB6/O FOB Outlet Barb S/S 6mm

- FDBARB8/O FOB Outlet Barb S/S 8mm

- FDBARB10/O FOB Outlet Barb S/S 10mm

- FDBARB12/O FOB Outlet Barb S/S 12mm

- FDMBL/O FOB B-Lock Straight Outlet // Connects to 3/4″ B-Lock adaptor

- FDELBL FOB B-Lock Elbow Outlet 5/8bsp swivel nut // Connects to 3/4″ B-Lock adaptor *Requires FDMO5/8.

- FDMO5/8 FOB Outlet 5/8BSPM // Connects direct to 5/8″ B-lock or Pin valve

- FDMMA Manifold Adaptor/1/2″ Inline + nut & olive // For connection to beer manifolds to supply multiple points with the same beer.

- FDM1/2MM Nipple 1/2″/Suit micromatic ball valves.

FDHF Beer FOB Detector Bare / High Flow Tall

FDM Beer FOB Detector Bare / High Flow short

FDBARB6/I FOB Inlet Barb / S/S 6mm

FDBARB8/I FOB Inlet Barb / S/S 8mm

FDBARB10/I FOB Inlet Barb / S/S 10mm

FDBARB12/I FOB Inlet Barb / S/S 12mm

FDBARBG56 FOB Inlet Barb /G56 Beer pump – Short

FDBARBG56EXT FOB Inlet Barb /G56 Beer pump – Long

FDBARB6/O FOB Outlet Barb S/S 6mm

FDBARB8/O FOB Outlet Barb S/S 8mm

FDBARB10/O FOB Outlet Barb S/S 10mm

FDBARB12/O FOB Outlet Barb S/S 12mm

FDMO5/8 FOB Outlet 5/8BSPM

FDMMA Manifold Adaptor/1/2″ Inline + nut & olive.

FDM1/2MM Nipple 1/2″/Suit micromatic ball valves.

CORE BEER FOB DETECTORS

Bracton is the Australian distributor of Core Components Beer FOB detector range. The core range of FOB detectors have been precision manufactured to minimise hygiene issues and deliver perfect performance at and affordable price.

- Reduce beer waste – increase profit.

- Stainless steel FOB Detectors designed to eliminate hygiene problems of most other fob detectors.

- Self sealing spring-action venting mechanism external to the beer flow.

- Rotating vent for easy installation.

- Symmetrically shaped float means no unhygienic guide pins and screws.

- Fully tapered base prevents the build up of beer stone in the corners.

- Optimal sight glass seal which eliminates unhygienic gaps unlike typical face groove design.

FDFEX02-XL Fob Detector / 1-3 Taps

FDFEX15 FOB W/ IN-LINE G56 CONNECTION/ 1-4 Taps

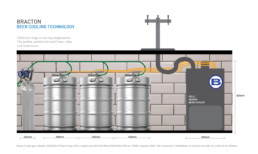

BRACTON FOB DETECTOR – BEER PUMP MANIFOLDS

Installing Bracton’s beer pump solution reduces beer gas consumption by 50 – 70% and increases the quality and life span of beer. The beer pump solution achieves this by reducing the volume of gas pressure required at the keg to enough to drive the beer from the keg to the beer pump (approximately 100kPa). Lower pressure at the keg also prevents over carbonation of the beer.

Bracton’s stainless steel FOB to beer pump manifolds minimise leak points, increase hygiene and help maintain a tidy cellar tapping board.

FJGSINGLE Beer Pump / 1xG56 W/ fob, FDMMA out

FJGDUAL Beer Pump / 2xG56 W/ fob, FDMMA out

FJGDUALFRV Beer Pump / 2xG56 W/ fob & FRV FDMMA out

BLOCK MANIFOLDS

Connect multiple taps to the one beer brand with ease. Bracton block manifolds deliver a scalable beer distribution solution from small hotels to stadium installations.

MBL010 Manifold nipple 3/4″ S/S

MBL020 Manifold Plug 3/4″ S/S

MBL050 Block Manifold c/w Bracket / 1 Way

MBL100 Block Manifold Elbow Adaptor

MBL200 Block Manifold c/w Bracket / 2 Way

MBL300 Block Manifold c/w Bracket / 3 Way

MBL400 Block Manifold c/w Bracket / 4 Way

Hybrid beer coolers

Hybrid Beer Coolers

Sub Zero Hybrid Icebank Beer Coolers

The latest in hybrid icebank beer chilling technology for bars and cafes. Utilising Bracton’s custom made Celli Icebank chassis, for the first time small venues can have frozen beer fonts and glycol temperature beers poured from ambient kegs at a fraction of the cost of a standard glycol cooler. This technology is exclusive to Bracton authorised distributors.

- Hybrid Icebank built for Australian conditions

- High energy efficiency – advanced insulation

- Longest product lines in industry

- For the coldest dispensed beer

- Chills to as low as -1.5C from a 25C keg

- Stainless case and floor pan

- Ideal for salty environments

- Rapid ice bank discharge hose (no need to siphon)

- New fluid forms ice bank at -2 to -4C

- Horizontal and vertical options

- New stylish front panel with cover inside to protect electrical parts

LITRE DISPENSED @ 16C / 24C / 32C / 43C

GEO20 – 53 / 32 / 23 / 16

GEO30 – 100 / 60 / 43 / 31

GEO50 – 147 / 88 / 63 / 45

GEO75 – 227 / 136 / 97 / 70

BRAVE90 – 260 / 156 / 111/ 80

GEO20V Vertical / 1/5HP / 8Kg Bank / 2 Coil

GEO30V Vertical / 1/3HP / 15Kg Bank / 3 Coil

GEO50V Vertical / 1/2HP / 22Kg Bank / 4 Coil

GEO50H Horizontal / 1/2HP / 22Kg Bank / 5 Coil

GEO75H Horizontal / 3/4HP / 35Kg Bank / 6 Coil

BRAVE90BC Horizontal / 1HP / 39Kg Bank / 6 Coil

ECOVC Hybrid Icebank Conversion of Vertical

ECOHC Hybrid Icebank Conversion of Horizonal

CT1000 Cooltube / Single Product

CT4000 Cooltube / Four Product

2FLOW25 Hybrid Icebank 2Flow Coolant 25Kg

(Freeze point -2)

4FLOW25 Hybrid Icebank 4Flow Coolant 25Kg

(Freeze point -4)

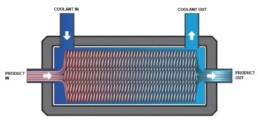

Cool Tube Heat Exchanger – Compact

The World’s smartest and smallest tube heat exchanger for drinks dispense. The Future of Dispense.

CoolTube is an amazingly efficient compact heat exchanger that provides superior heat exchange capabilities and also allows variable dispense temperatures at the point of dispense. CoolTube is compatible with any coolant medium, enabling installation and compatibility to all current dispense systems.

This patented technology is set to change the future of dispensed beverages.

CoolTube is constructed from stainless steel throughout and is over six times smaller and lighter than a standard remote cooling pod and has a superior delta T in comparison to competitive products. The product is so compact and lightweight that it doesn’t require fixings, therefore can fit in most confined spaces including directly under the font, saving valuable space behind the bar.

Dispensed drinks temperatures can be within 1ºC to 2ºC of the python recirculation temperature. There is very little variation in dispensed temperatures whether or not a half pint is poured or the tap is constantly opened. This is due to the low volume actually within the CoolTube and its unique tube heat exchanger technology.

CoolTube is easy to install and delivers outstanding results so as a time and space saving device it’s second to none. The product is compatible with all standard industry push in fittings and comes in two standard sizes (1 way and 4 way). The technology can also be adapted into the dispense font/tower.

All stainless steel components are made from high quality grade 316.

Benefits

- Works with Bracton Glycol or Hybrid Icebank Technology

- Over 6 times smaller and lighter than standard heat exchangers.

- Holds up to 80% less coolant than other products.

- Has a superior delta T in comparison to other products.

- No product coils required in the primary cooler creating greater efficiencies.

- Variable temperatures across all dispense points ranging from sub zero to ambient product.

- Massively reduces line cleaning losses.

- Allows smaller coolers with substantial energy savings.

- One simple change of the coolant flow rate will change the product dispense temperature instantly.

Features

- Has the equivalent of 18 meters of product coil.

- So compact and light weight that it doesn’t need fixing into position.

- Fits into the most confined spaces, including directly under the font, saving valuable spance behind the bar.

- Has over 4 times more cooling surface area per ml of product than a standard heat exchanger.

- Dispensed drinks temperatures can be within 1ºC – 2ºC of the python recirculation temperature.

- Stable dispenser temperatures due to the low volume of product within the CoolTube and its unique heat exchange technology. Thus removing any dwell pint issues.

- Scope to include the technology inside the post of dispense.

- CoolTube has over 4 times more cooling surface area per ml of product than a standard pod and holds less than 80% of the amount of coolant. For example, the surface area cooling of the beer coils in the CoolTube is 24cm² per ml of beer. This compares to other heat exchanger products which have less than 6cm² per ml of beer surface area cooling.

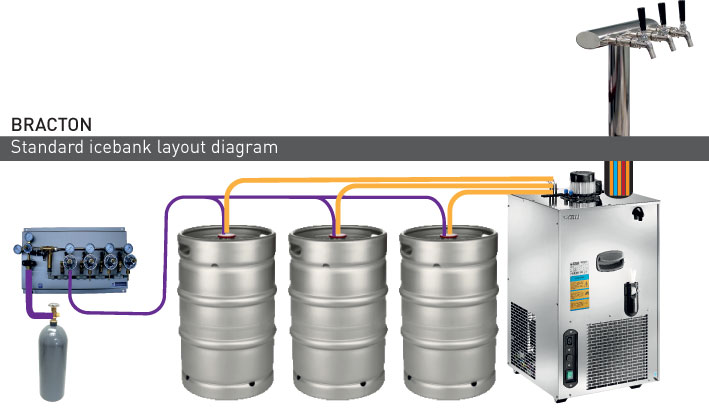

Ice bank beer coolers

Ice bank beer coolers

Bracton imports a complete range of Celli Ice Bank Beer Coolers made in Italy to our specification. Using the latest in production methods, our beer ice banks are built for Australian conditions, using stainless steel bodies to withstand our harsh environment.

Ice Bank Beer Coolers

The Celli Ice Bank Coolers have extra long product coils to ensure beer is dispensed at the optimum temperature. Reliable European built condensers ensure years of quality performance without failure. Tested to Australian Standards AS/NZS 60335.1 & AS/NZS 60335.2.75

- Built for Australian conditions

- High energy efficiency – advanced insulation

- Longest product lines in industry

- For the coldest ice bank dispensed beer

- Stainless case and floor pan

- Ideal for salty environments

- Rapid ice bank discharge hose (no need to siphon)

- Casing with integrated pump and coils

- Horizontal and vertical options

- New stylish front panel with cover inside to protect electrical parts

For frozen or iced fonts, consider upgrading your ice bank to Bracton’s SubZero hybrid technology. Delivering the benefits of a glycol system with reserve cooling capacity.

Bracton GEO Series have been tested to Australian electrical standards AS/NZ60335.1 & AS/NZ60335.2.75

MOST ICE BANKS IN AUSTRALIA HAVE NOT BEEN TESTED TO AUSTRALIAN STANDARDS.

| GEO27V R290

Coils: 3 Dispense capacity until icebank depleted; 16°C-80L |

GEO50V R290

Coils: 4 (5 option) Dispense capacity until icebank depleted; 16°C-147L |

GEO50H R290

Coils: 4 (5 option) Dispense capacity until icebank depleted; 16°C-147L |

GEO75H R290

Coils: 6 (7 option) Dispense capacity until icebank depleted; 16°C-227L |

BRAVE90BC

Coils: 6 (8 option) Dispense capacity until icebank depleted; 16°C-260L |

GEO27V Vertical / 1/4HP / 12Kg Bank / 3 Coil (383x383x711mm WDH)

GEO50V Vertical / 1/2HP / 22Kg Bank / 4 Coil (439x439x818mm WDH)

GEO50H Horizontal / 1/2HP / 22Kg Bank / 4 Coil (645x441x542mm WDH)

GEO75H Horizontal / 3/4HP / 35Kg Bank / 6 Coil (767x557x564mm WDH)

BRAVE90BC Horizontal / 1HP / 39Kg Bank / 6 Coil (887x552x736mm WDH)

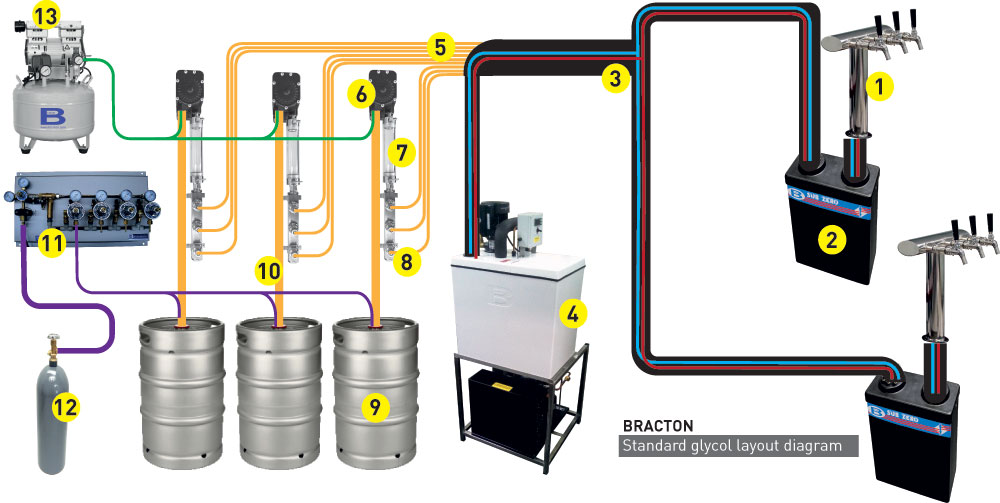

Glycol Beer Chillers

Glycol Beer Chillers

Bracton manufactures a range of high performance glycol beer chillers ranging from 1kW to 100kW. Our glycol beer chillers platform is highly flexible allowing the perfect configuration for your specific cooling load. Ideal for beer dispense or brewery cooling applications.

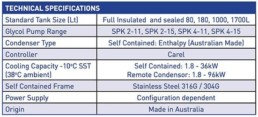

SELF CONTAINED GLYCOL BEER CHILLERS

Ideal for smaller applications, designed to plug-in and switch on, no refrigeration technician required.

Engineered. Reliable.

The Self Contained Sub Zero Glycol Beer Chiller is the latest in Bracton’s plug and pour range of glycol chillers. Engineered to provide years of trouble free reliable service, these systems are ideal for small commercial applications including country hotels, bowling clubs. Engineered to be affordable and reliable.

Energy efficient design

High thermal efficiency fibreglass tank minimised heat loss from tank in all Australian conditions.

Plug and pour

Designed to reduce installation costs. No need for refrigeration technician. No fuss installation. Plug in, fill up and turn on.

Features:

- Robust 80Lt or 180Lt tank

- Hermetic condenser

- High flow glycol connections

- P-Trap over flow

- Ideal for small venues

- Suitable for coolroom or ambient installation

- Australian made for all conditions including tropical environments

SZSC3300 Glycol Beer Chiller Self Contained/ 3.3Kw (-10SST)

SZSC2800 Glycol Beer Chiller Self Contained/ 2.8Kw (-10SST)

SZSC1800 Glycol Beer Chiller Self Contained/ 1.8Kw (-10SST)

For information on sizing a glycol chiller for your hotel, contact Bracton on +61 2 9938 1800.

REMOTE GLYCOL BEER CHILLERS – SUB ZERO RANGE

Ideal for small to large scale beer dispense and brewery glycol crash chilling. By separating the chiller from the condensing unit you can direct unwanted heat outside of the building and maintain a low noise environment.

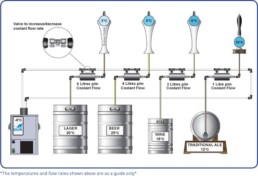

Remote Glycol Beer Chiller reticulation systems

The most popular beer cooling systems in Australian hotels. This design is recognised as a consistent performer in all environments. Bracton’s chassis designed provides supreme flexibility and customisation, making the ideal choice where performance and reliability matter. Suitable for installation in cool room or ambient.

Standard options

- 3, 5, 8, 10, 12, 14, 16kW

- Grundfos SPK2-11, SPK4-11 or SPK4-15

- Single or Dual Pump Redundancy

- Refrigerant options: R404a, R134a orR22

- 180 Litre tank

- Will not condensate in ambient conditions

GLYCOL MANIFOLDS

High flow rate design

Bracton designed performance manifolds ensure high glycol throughput, increasing the efficiency of the whole draught pump system. Aiding in icing of beer fonts, through the summer months. Available in a full range of configurations.

Supply manifolds are fitted standard with ball-valves, insulation and wall mount brackets. 1/2″ barbs fitted to ball valves and 1″ hose barbs fitted for connection to Glycol Beer Chiller.

SMAN21 Glycol Manifold/Supply/2 Point/1 Pump

SMAN22 Glycol Chiller Manifold/Supply/2 Point/2 Pump

SMAN41 Glycol Chiller Manifold/Supply/4 Point/1 Pump

SMAN42 Glycol Chiller Manifold/Supply/4 Point/2 Pump

SMAN61 Glycol Chiller Manifold/Supply/6 Point/1 Pump

SMAN62 Glycol Chiller Manifold/Supply/6 Point/2 Pump

SMAN81 Glycol Chiller Manifold/Supply/8 Point/1 Pump

SMAN82 Glycol Chiller Manifold/Supply/8 Point/2 Pump

SMAN101 Glycol Chiller Manifold/Supply/10 Point/1 Pump

SMAN102 Glycol Chiller Manifold/Supply/10 Point/2 Pump

SMAN121 Glycol Chiller Manifold/Supply/12 Point/1 Pump

SMAN122 Glycol Chiller Manifold/Supply/12 Point/2 Pump

SMAN141 Glycol Chiller Manifold/Supply/14 Point/1 Pump

SMAN142 Glycol Chiller Manifold/Supply/14 Point/2 Pump

SMAN141 Glycol Chiller Manifold/Supply/16 Point/1 Pump

SMAN142 Glycol Chiller Manifold/Supply/16 Point/2 Pump

RMAN2 Glycol Chiller Manifold/Return/2 Point

RMAN4 Glycol Chiller Manifold/Return/4 Point

RMAN6 Glycol Chiller Manifold/Return/6 Point

RMAN8 Glycol Chiller Manifold/Return/8 Point

RMAN10 Glycol Chiller Manifold/Return/10 Point

RMAN12 Glycol Chiller Manifold/Return/12 Point

RMAN14 Glycol Chiller Manifold/Return/14 Point

RMAN15 Glycol Chiller Manifold/Return/16 Point

Cooling Equipment

Bracton manufactures and imports a full range of beer cooling equipment and soft drink cooling systems for venues of all sizes from stadiums to cafe's. Our range of commercial beverage cooling equipment is second to none and has been designed for use in Australian environment, built to last. For technical or sales assistance contact a Bracton expert today.

Glycol Beer Cooling Equipment

Bracton glycol chiller / cooling systems are the essential choice for medium to high volume draught beer cooling applications such as hotels and stadiums. Our bespoke glycol chiller units allow for a range of built-in redundancy, pump and cooling configurations to suit your specific requirements. Bracton Glycol Chillers available in remote tank or self contained. Click here for more information on Bracton glycol chillers.

Ice Bank Beer Cooling Equipment

Ice bank cooling systems are ideal for the smaller draught beer cooling applications ie bars, restaurants or home use. Low maintenance high efficiency units are manufactured to meet the highest standards. Click here for more information on Ice Bank Beer Cooling Equipment.

Post Mix Cooling and Carbonating Systems (Soft Drink)

Celli Post Mix coolers and carbonator have been leading the world in soft drink dispense technology since 1974. Relied upon around the world to deliver quality soft drink, Celli post mix systems are you guarantee for reliability and efficiency. Available in Counter Top Systems or Under Counter / Back of House Systems. Click here for more information on Post Mix Cooling and Carbonating Systems.

Mobile Bars & Counter Top Cooling

Bracton plug and pour mobile draught beer systems are quick to set up and easy to use. Ideal for areas where space is a premium, hiring out, functions and pop-up bars. Click here for more information on Mobile Bars & Counter Top beer coolers

Keg Fridges - Direct Draw Beer Dispense

Keg fridges direct draw systems, serve draught beer direct economically from refrigerated cabinets under the bench. Low cost solution for function centres, bars and restaurants. Click here for more information on Keg Fridges.

Mobile Beer Coolers

Mobile Beer Coolers

Bracton manufactures and imports a complete range of temporary, portable and mobile bars for dispensing beer and other alcoholic drinks. Our mobile bars are available in a range of sizes, including small jockey box beer systems to large scale beer dispensing systems. Bracton beer equipment powers dispense at events including Laneway Festival, Melbourne Cup Carnival and F1 Singapore catering for over 100,000 at one event.

MOBILE BAR – BEER COOLER ON WHEELS

Bracton in partnership with Celli has designed mobile ice banks with stainless construction. Built for harsh Australian conditions. All systems are simple to operate, simply fill with water, switch on, wait an hour then pour. Ideal for hotels and festivals.

LITRE DISPENSED @ 16C / 24C / 32C / 43C

GEO50C – 147 / 88 / 63 / 45

GEO75C – 227 / 136 / 97 / 70

BRAVE90 – 260 / 156 / 111/ 80

Note: once ice bank is depleted, recovery period is required to build up ice bank.

GEO50C-2 1/2HP / 22Kg Ice / 2 Product

GEO75C-3 3/4HP / 35Kg Ice / 3 Product

BRAVE90C 1HP / 39Kg Ice / 3 Product

MOBILE KEG FRIDGES

Introducing the all new Bracton direct draw Sub Zero series beer dispensers. Stainless steel inside and out the range has been designed to store, chill and dispense from standard commercial beer kegs.

Dispense towers are sold separately. Standard or bespoke towers are available. Visit our font page to see our options.

BDD1S 1 DOOR / 1 KEG FRIDGE

BDD2S 2 DOOR / 2 KEG FRIDGE

BDD3S 3 DOOR / 3 KEG FRIDGE OR 2 KEG + BOTTLE SHELVING

PORTABLE BARS WITH BUILT-IN ICEBANK OR ICE PLATE COOLING

Bracton manufacture a full range of custom portable bars for beer dispense. Utilising our extensive range of beer fonts and beer chillers, you can select the ideal beer font and chiller for your application. For more information contact us.

CUSTOM ORDER

COUNTER TOP BEER COOLER BOX

Ideal for restaurants and cafes.

BALI1 Countertop Beer Cooler / 3Kg Bank / 1/6HP /1 tap

BALI2 Countertop Beer Cooler / 3Kg Bank / 1/6HP /2 tap

JOCKEY BOX BEER COOLER

Fill with ice and a little water, connect to beer and pour. Dispense without breakout. Cooler comes with gas regulator setting chart.

JOCKEYBOX 1BEER

JOCKEYBOX 2BEER

TABLE BEER TOWER ICE COOLED

Fill with ice and beer then pour. A great option for summer parties and outdoor bars.

TABLE/BEER/TOWER

Drip trays

Drip Trays

Bracton manufactures and imports a large range of beer font drip trays, made from quality 304 Grade Stainless Steel. Available in plinth, recessed or pressed.

PLINTH DRIP TRAYS

Designed to sit on top of bench, Ideal for heavy fonts and fast to install.

Construction: Premium Stainless Steel 304G, resin filled for extra rigidity.

DT7010 355 x 250mm

DT7020 355 x 350mm

DT7030 355 x 450mm

DT7040 355 x 550mm

DT7050 355 x 750mm

DT7060 355 x 950mm

DT7070 355 x 1100mm

DT7080 355 x 1500mm

Note: Dimensions refer to internal tray area.

RECESSED DRIP TRAYS

Designed to be countersunk into bar counter top, Ideal for fast timber installations.

Construction: Premium Stainless Steel 304G, resin filled for extra rigidity.

DT6010 355 x 250mm

DT6020 355 x 350mm

DT6030 355 x 450mm

DT6040 355 x 550mm

DT6050 355 x 750mm

DT6060 355 x 950mm

DT6070 355 x 1100mm

DT6080 355 x 1500mm

Note: Dimensions refer to internal tray area.

Specification and installation diagram

PRESSED DRIP TRAYS

Low cost pressed stainless steel drip tray.

Construction: Stainless Steel 304G, includes plastic reinforcement pieces.

DT3010 400 x 400mm

DT3020 600 x 400mm

DT3030 800 x 400mm

PRESSED DRIP TRAY WITH GLASS RINSER

Low cost pressed stainless steel drip tray with built in glass rinser.

Construction: Stainless Steel 304G

DT4010 400 x 400mm

DT4020 600 x 400mm

DT4030 800 x 400mm

PRESSED SMALL DRIP TRAYS

Low cost pressed stainless steel drip tray.

Construction: Stainless Steel 304G.

DT5010 200 x 180mm

DT5020 300 x 180mm

BENCH CLAMP ON DRIP TRAYS

No tools required installation, simply side on to countertop and hand tighten clamp. Ideal for temporary installations.

Construction: Powder coat steel

62819 Standard with plastic clamp-on drip tray

56820 Premium with stainless clamp-on drip tray

Beer taps + accessories

Beer taps + accessories

PERLICK 630SS - Hygienic Beer Taps

Perlick’s 304 stainless steel, forward sealing beer and wine taps are unique in both appearance and function. A revolutionary ball and floating front seal design prevents beer from being exposed to air. As a result, the handle lever doesn’t stick and there is no build up of mould and bacteria in the tap body, delivering a complete clean during a regular beer line clean.

Fewer internal parts means better reliability and fewer service calls.

TA1061 Beer Taps/630SS/B-lock Shank & Handle (Snap-Lok & Fat-Lock compatible)

TA1062 Beer Taps/630SS/Bare

PERLICK 650SS - FLOW CONTROL TAP

Features a Flow Control Handle on the side of the faucet, which can adjust restriction for hard to pour brands or to slow the pour for sampler glasses.

- Stainless Steel construction – won’t pit or tarnish.

- Patented forward sealing design eliminates the need for a valve shaft exposed to beer and air

- Spout angle is more vertical allowing a more thorough draining after each pour – no horizontal area for beer to collect

- Polished interior – smooth flow, less agitation and less foaming

- Easy to clean – may be cleaned in place

TA1063 Beer Taps/650SS/B-lock Shank & Handle (Snap-Lok & Fat-Lock compatible)

TA1064 Beer Taps/650SS/Bare

UNIVERSAL STAINLESS STEEL BEER TAP

The classic Bracton universal beer tap are trusted by tens of thousands of hotels and clubs. Precision manufactured to our custom design using 304 high grade stainless steel, these taps reliably deliver the perfect glass of beer every time.

TA1015 UNIVERSAL BEER TAP (BARE)

TA1010 UNIVERSAL BEER TAP B-LOCK SHANK, BEER TAP HANDLE AND COUPLER NUT

BEER TAP SERVICE KITS (TAP O-RINGS)

Rebuilding beer taps? Our OEM Perlick and Bracton service kits are quick an easy to install

TA1930 PERLICK 630/650SS MAIN SEAL KIT

TA1950 PERLICK 650SS FLOW CONTROL KIT

TA1997 BEER TAP SERVICE KIT / PERLICK 525

TA1998 BEER TAP SERVICE KIT / PERLICK 425

TA1999 BEER TAP SERVICE KIT / UNIVERSAL / IRIDIUM / GRUNDY

TA2999 BEER TAP SERVICE KIT / CAULFIELD TAP

TA4999 BEER TAP SERVICE KIT / BEER GUN

BEER TAP DECAL FLAGS (BRANDING HOLDERS)

Decal flags can be applied to almost any dispense font to attach branding. Available in chrome or copper finish. connects to 32-42mm spigots.

FA2010-C Beer Decal holder / Chrome

FA2010-CU Beer Decal holder / Copper

TAP PANEL EXTENSION (SHANK)

Stainless steel panel extensions, ideal for passing through cool room walls, eskys and the alike.

FA1085 5/8″bspm x 1/2″bsp x 3″

SS 1/4″bsp internal thread

Suits 5/8″ B-lock adaptor

(Snap-Lok & Fat-Lock compatible)

FA1090 Perlick 2.5″ / with coupler nut

FA1100 Perlick 6″ / with coupler nut

FA1110 Perlick 8″ / with coupler nut

BEER TAP HANDLES

Beer tap handles designed to suit all standard tap threads.

TA1150 Tap Handle / Black

TA1156 Tap Handle / Wood

TA1155 Tap Handle / Aluminium Satin

TA1157 Tap Handle / Premium Black Onyx

TA1158 Tap Handle / Premium White Onyx

BEER TAP KLEEN PLUGS

Keep your beer taps clean and safe with the Bracton beer tap plug.

These innovative plugs are inserted into the ends of your beer tap, and when removed, they help eliminate the build-up of contaminants and microorganisms that cause bad tasting beer and pose a health risk.

When not in use, soak the clean plugs in Bracton Keg Coupling no rinse formulation to ensure sanitary use every time.

TA1175 10 pack

TA1180 50 pack

TA1182 Kit (10 pack + sanitiser + soak container)

BEER TAP WRENCH / C SPANNER

Makes tap shank assembly / disassembly a breeze.

TA1160 C-Spanner

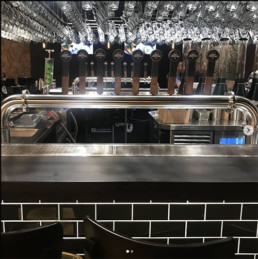

Beer fonts & towers

Beer + wine dispense fonts

We specialise in the design and manufacture of beer fonts in a wide range of configurations and finishes. We offer in-house designs and bespoke beer font design service for venues and brands seeking a unique solution, whether it be a single or a 48 tap beer font.

TEE BAR FONTS

NUMBER OF TAPS: 1 – 12

COOLING METHOD: Flooded or Recirculated

RISER LINE SIZE: 4 or 5 mm

TOWER CONNECTION: 3/4” or direct tower to tap

BROOKLYN FONT

NUMBER OF TAPS: 4 – 22

COOLING METHOD: Flooded or Recirculated

RISER LINE SIZE: 4 or 5 mm

TOWER CONNECTION: 3/4” or direct tower to tap

CHARLIE + HOCKEY FONTS

NUMBER OF TAPS: 1 or 2 Taps

COOLING METHOD: Flooded or Recirculated

RISER LINE SIZE: 4 or 5 mm

TOWER CONNECTION: 3/4” or direct tower to tap

WEMBLEY FONTS

NUMBER OF TAPS: 4 – 20

COOLING METHOD: Flooded or Recirculated

RISER LINE SIZE: 4 or 5 mm

TOWER CONNECTION: 3/4” or direct tower to tap

NUMBER OF TAPS: 4 – 10

COOLING METHOD: Flooded or Recirculated

RISER LINE SIZE: 4 or 5 mm

TOWER CONNECTION: 3/4” or direct tower to tap

NUMBER OF TAPS: 4 – 40

COOLING METHOD: Flooded or Recirculated

RISER LINE SIZE: 4 or 5 mm

TOWER CONNECTION: 3/4” or direct tower to tap

NUMBER OF TAPS: 4 – 12

COOLING METHOD: Flooded or Recirculated

RISER LINE SIZE: 4 or 5 mm

TOWER CONNECTION: 3/4” or direct tower to tap

NUMBER OF TAPS: 4 – 12

COOLING METHOD: Flooded or Recirculated

RISER LINE SIZE: 4 or 5 mm

TOWER CONNECTION: 3/4” or direct tower to tap

NUMBER OF TAPS: 4 – 12

COOLING METHOD: Flooded or Recirculated

RISER LINE SIZE: 4 or 5 mm

TOWER CONNECTION: 3/4” or direct tower to tap

NUMBER OF TAPS: 4 – 20

COOLING METHOD: Flooded or Recirculated

RISER LINE SIZE: 4 or 5 mm

TOWER CONNECTION: 3/4” or direct tower to tap

NUMBER OF TAPS: 6 – 24

COOLING METHOD: Flooded or Recirculated

RISER LINE SIZE: 4 or 5 mm

TOWER CONNECTION: 3/4” or direct tower to tap

NUMBER OF TAPS: 4 – 16

COOLING METHOD: Flooded or Recirculated

RISER LINE SIZE: 4 or 5 mm

TOWER CONNECTION: 3/4” or direct tower to tap

Whale Tail

V8 Font

K2 Font

Juliette Font

Cobra Font

Glycol Beer Coolers

Glycol Beer Coolers Ice Bank Beer Coolers

Ice Bank Beer Coolers Hybrid Sub Zero Coolers

Hybrid Sub Zero Coolers Mobile Coolers

Mobile Coolers Postmix Coolers

Postmix Coolers Keg Fridges

Keg Fridges