Distilled Water

BRACTON DISTILLED WATER

Bracton manufactures high quality distilled water by vapour recompression distillation process meaning we produce one of the highest grades of industrial and commercial distilled water in Australia. The Bracton distillation process removes minerals, salts, viruses, bacteria, cysts, heavy metals, radionuclides, organic’s, inorganic’s, and particulates leaving a pure product suitable for a range of industrial, commercial and residential applications.

- Pharmaceutical distilled water

- Distilled water for cleaning industries

- Supermarket distilled water

- Automotive distilled water

- Hardware distilled water

- Industrial distilled water

NOTE: Distilled water is demineralised, though demineralised water is not necessarily distilled.

Standard Packaging

3x5L Cartons

25L

200L

1000L

Palletised distilled water

72 x Cartons (3x5L)

32 x 25L Drums

4 x 200L Drum

1000L

Refill

IBC Refill options available, min refill order 200Lt.

Private / Custom Label : options available on request

Distilled water has many applications where a very high level of water purity is required. Below is a list of distilled waters key applications.

INDUSTRIAL DISTILLED WATER

- Mechanical Engineering & Motor Industries – Distilled water is preferable to tap water for use in automotive cooling systems. The minerals and ions typically found in tap water can be corrosive to internal engine components, and can cause a more rapid depletion of the anti-corrosion additives found in most antifreeze formulations.

- Wet cell battery servicing – Distilled water is also commonly used to top up lead acid batteries used in forklifts, cars and trucks. The presence of other impurities commonly found in tap water will significantly reduce battery lifespan.

- Laboratories Pharmaceutical companies

- Petrochemical and chemical

- Laser cutting

- Electronics manufacturing facilities

- Drilling rigs and marine desalination

COMMERCIAL DISTILLED WATER

- Heat Exchange Systems – ie Dilution of Propylene Glycol or Ethylene Glycol Systems.

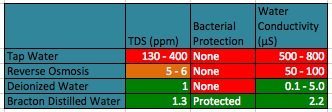

- Auto Clave Sterilising by surgeries and laboratories – conductivity of 2 µs/cm and a TDS (total dissolved solids) 1.38 ppm.

- Photographic Labs

- Hospitals and Doctor’s Rooms

- Hair Salons – Chlorine free rinsing of hair

- Laundromat / Ironing – using distilled water in steam irons for pressing clothes can help reduce mineral build-up and make the iron last longer.

- Continuous Positive Airway Pressure (CPAP) machines

- Radiator coolants

- Dentistry

- School Science Laboratories

Technical

The effects of poor quality water often go unnoticed, however in many industrial and commercial applications, equipment life can be extended and unscheduled down time can be reduced by choosing higher quality water. Understanding the importance of water quality is critical.

Which quality of water is right for your application?

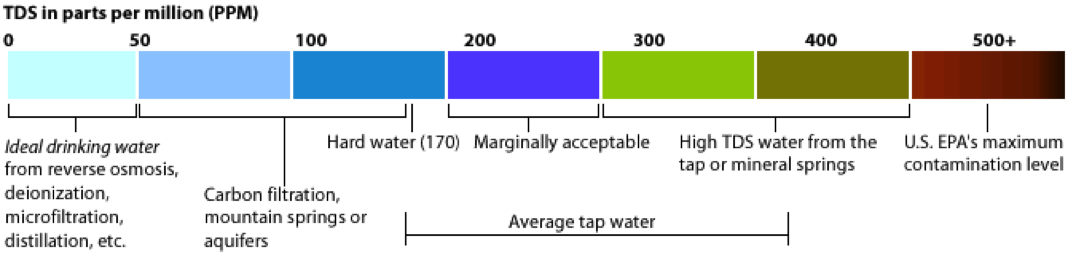

Total Dissolved Solids (TDS) are the total amount of mobile charged ions, including metals minerals or salts dissolved water, generally expressed in units of mg per unit volume of water (mg/L), also referred to as parts per million (ppm).

Total Dissolved Solids (TDS) are the total amount of mobile charged ions, including metals minerals or salts dissolved water, generally expressed in units of mg per unit volume of water (mg/L), also referred to as parts per million (ppm).

In general, the lower the Total Dissolved Solids concentration the better for industrial and commercial applications. Distilled water has virtually zero conductivity. Conductivity is usually about 100 times the total cations or anions expressed as equivalents. TDS is calculated by converting the EC by a factor of 0.5 to 1.0 times the EC, depending upon the levels. Typically, the higher the level of EC, the higher the conversion factor to determine the TDS. NOTE – While a TDS meter is based on conductivity, TDS and conductivity are not the same.

Why use distilled water over reverse osmosis?

Technical advances, in the Bracton distillation system, allow production of distilled water to ≤ 1 ppm total dissolved solids (TDS). The Bracton water distillation process consistently removes about 99.9% of the contaminants, while the best reverse osmosis systems start at about 98%, then rapidly degrades pending the type installed reverse osmosis (RO) system.

The small pores in the membrane of reverse osmosis systems block particles of large molecular structure like salt, though more dangerous chemicals like pesticides, herbicides, and chlorine are molecularly smaller than water, thus are not cleaned from water produced by reverse osmosis.

Contrastingly distillation, more specifically vapour recompression distillation, will remove any chemicals or organic materials with higher boiling points than water. Such chemicals and organic materials with higher boiling points include minerals*, trace amounts of metals, many volatile organic chemicals (VOCs), and nitrate.

The process of distillation kills and removes virtually all bacteria, viruses and other organic and inorganic contaminants, making Bracton Distilled Water the ideal water for use in most industrial applications. Minerals include salt, manganese, iron, fluoride, lead, and calcium. heavy metals include lead, arsenic, and mercury.