Glycol Beer Chillers

Bracton manufactures a range of high performance glycol beer chillers ranging from 1kW to 100kW. Our glycol beer chillers platform is highly flexible allowing the perfect configuration for your specific cooling load. Ideal for beer dispense or brewery cooling applications.

SELF CONTAINED GLYCOL BEER CHILLERS

Ideal for smaller applications, designed to plug-in and switch on, no refrigeration technician required.

Engineered. Reliable.

The Self Contained Sub Zero Glycol Beer Chiller is the latest in Bracton’s plug and pour range of glycol chillers. Engineered to provide years of trouble free reliable service, these systems are ideal for small commercial applications including country hotels, bowling clubs. Engineered to be affordable and reliable.

Energy efficient design

High thermal efficiency fibreglass tank minimised heat loss from tank in all Australian conditions.

Plug and pour

Designed to reduce installation costs. No need for refrigeration technician. No fuss installation. Plug in, fill up and turn on.

Features:

- Robust 80Lt or 180Lt tank

- Hermetic condenser

- High flow glycol connections

- P-Trap over flow

- Ideal for small venues

- Suitable for coolroom or ambient installation

- Australian made for all conditions including tropical environments

SZSC3300 Glycol Beer Chiller Self Contained/ 3.3Kw (-10SST)

SZSC2800 Glycol Beer Chiller Self Contained/ 2.8Kw (-10SST)

SZSC1800 Glycol Beer Chiller Self Contained/ 1.8Kw (-10SST)

For information on sizing a glycol chiller for your hotel, contact Bracton on +61 2 9938 1800.

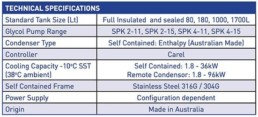

REMOTE GLYCOL BEER CHILLERS – SUB ZERO RANGE

Ideal for small to large scale beer dispense and brewery glycol crash chilling. By separating the chiller from the condensing unit you can direct unwanted heat outside of the building and maintain a low noise environment.

Remote Glycol Beer Chiller reticulation systems

The most popular beer cooling systems in Australian hotels. This design is recognised as a consistent performer in all environments. Bracton’s chassis designed provides supreme flexibility and customisation, making the ideal choice where performance and reliability matter. Suitable for installation in cool room or ambient.

Standard options

- 3, 5, 8, 10, 12, 14, 16kW

- Grundfos SPK2-11, SPK4-11 or SPK4-15

- Single or Dual Pump Redundancy

- Refrigerant options: R404a, R134a orR22

- 180 Litre tank

- Will not condensate in ambient conditions

GLYCOL MANIFOLDS

High flow rate design

Bracton designed performance manifolds ensure high glycol throughput, increasing the efficiency of the whole draught pump system. Aiding in icing of beer fonts, through the summer months. Available in a full range of configurations.

Supply manifolds are fitted standard with ball-valves, insulation and wall mount brackets. 1/2″ barbs fitted to ball valves and 1″ hose barbs fitted for connection to Glycol Beer Chiller.

SMAN21 Glycol Manifold/Supply/2 Point/1 Pump

SMAN22 Glycol Chiller Manifold/Supply/2 Point/2 Pump

SMAN41 Glycol Chiller Manifold/Supply/4 Point/1 Pump

SMAN42 Glycol Chiller Manifold/Supply/4 Point/2 Pump

SMAN61 Glycol Chiller Manifold/Supply/6 Point/1 Pump

SMAN62 Glycol Chiller Manifold/Supply/6 Point/2 Pump

SMAN81 Glycol Chiller Manifold/Supply/8 Point/1 Pump

SMAN82 Glycol Chiller Manifold/Supply/8 Point/2 Pump

SMAN101 Glycol Chiller Manifold/Supply/10 Point/1 Pump

SMAN102 Glycol Chiller Manifold/Supply/10 Point/2 Pump

SMAN121 Glycol Chiller Manifold/Supply/12 Point/1 Pump

SMAN122 Glycol Chiller Manifold/Supply/12 Point/2 Pump

SMAN141 Glycol Chiller Manifold/Supply/14 Point/1 Pump

SMAN142 Glycol Chiller Manifold/Supply/14 Point/2 Pump

SMAN141 Glycol Chiller Manifold/Supply/16 Point/1 Pump

SMAN142 Glycol Chiller Manifold/Supply/16 Point/2 Pump

RMAN2 Glycol Chiller Manifold/Return/2 Point

RMAN4 Glycol Chiller Manifold/Return/4 Point

RMAN6 Glycol Chiller Manifold/Return/6 Point

RMAN8 Glycol Chiller Manifold/Return/8 Point

RMAN10 Glycol Chiller Manifold/Return/10 Point

RMAN12 Glycol Chiller Manifold/Return/12 Point

RMAN14 Glycol Chiller Manifold/Return/14 Point

RMAN15 Glycol Chiller Manifold/Return/16 Point