Hybrid Beer Coolers

Sub Zero Hybrid Icebank Beer Coolers

The latest in hybrid icebank beer chilling technology for bars and cafes. Utilising Bracton’s custom made Celli Icebank chassis, for the first time small venues can have frozen beer fonts and glycol temperature beers poured from ambient kegs at a fraction of the cost of a standard glycol cooler. This technology is exclusive to Bracton authorised distributors.

- Hybrid Icebank built for Australian conditions

- High energy efficiency – advanced insulation

- Longest product lines in industry

- For the coldest dispensed beer

- Chills to as low as -1.5C from a 25C keg

- Stainless case and floor pan

- Ideal for salty environments

- Rapid ice bank discharge hose (no need to siphon)

- New fluid forms ice bank at -2 to -4C

- Horizontal and vertical options

- New stylish front panel with cover inside to protect electrical parts

LITRE DISPENSED @ 16C / 24C / 32C / 43C

GEO20 – 53 / 32 / 23 / 16

GEO30 – 100 / 60 / 43 / 31

GEO50 – 147 / 88 / 63 / 45

GEO75 – 227 / 136 / 97 / 70

BRAVE90 – 260 / 156 / 111/ 80

GEO20V Vertical / 1/5HP / 8Kg Bank / 2 Coil

GEO30V Vertical / 1/3HP / 15Kg Bank / 3 Coil

GEO50V Vertical / 1/2HP / 22Kg Bank / 4 Coil

GEO50H Horizontal / 1/2HP / 22Kg Bank / 5 Coil

GEO75H Horizontal / 3/4HP / 35Kg Bank / 6 Coil

BRAVE90BC Horizontal / 1HP / 39Kg Bank / 6 Coil

ECOVC Hybrid Icebank Conversion of Vertical

ECOHC Hybrid Icebank Conversion of Horizonal

CT1000 Cooltube / Single Product

CT4000 Cooltube / Four Product

2FLOW25 Hybrid Icebank 2Flow Coolant 25Kg

(Freeze point -2)

4FLOW25 Hybrid Icebank 4Flow Coolant 25Kg

(Freeze point -4)

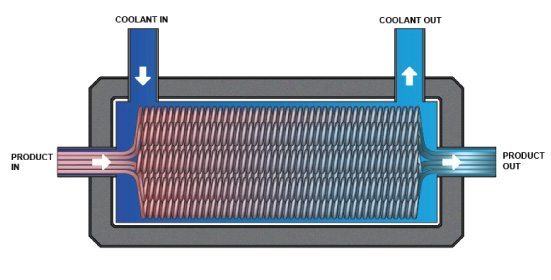

Cool Tube Heat Exchanger – Compact

The World’s smartest and smallest tube heat exchanger for drinks dispense. The Future of Dispense.

CoolTube is an amazingly efficient compact heat exchanger that provides superior heat exchange capabilities and also allows variable dispense temperatures at the point of dispense. CoolTube is compatible with any coolant medium, enabling installation and compatibility to all current dispense systems.

This patented technology is set to change the future of dispensed beverages.

CoolTube is constructed from stainless steel throughout and is over six times smaller and lighter than a standard remote cooling pod and has a superior delta T in comparison to competitive products. The product is so compact and lightweight that it doesn’t require fixings, therefore can fit in most confined spaces including directly under the font, saving valuable space behind the bar.

Dispensed drinks temperatures can be within 1ºC to 2ºC of the python recirculation temperature. There is very little variation in dispensed temperatures whether or not a half pint is poured or the tap is constantly opened. This is due to the low volume actually within the CoolTube and its unique tube heat exchanger technology.

CoolTube is easy to install and delivers outstanding results so as a time and space saving device it’s second to none. The product is compatible with all standard industry push in fittings and comes in two standard sizes (1 way and 4 way). The technology can also be adapted into the dispense font/tower.

All stainless steel components are made from high quality grade 316.

Benefits

- Works with Bracton Glycol or Hybrid Icebank Technology

- Over 6 times smaller and lighter than standard heat exchangers.

- Holds up to 80% less coolant than other products.

- Has a superior delta T in comparison to other products.

- No product coils required in the primary cooler creating greater efficiencies.

- Variable temperatures across all dispense points ranging from sub zero to ambient product.

- Massively reduces line cleaning losses.

- Allows smaller coolers with substantial energy savings.

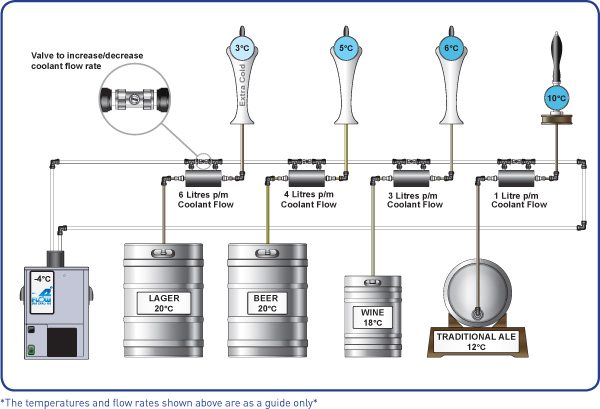

- One simple change of the coolant flow rate will change the product dispense temperature instantly.

Features

- Has the equivalent of 18 meters of product coil.

- So compact and light weight that it doesn’t need fixing into position.

- Fits into the most confined spaces, including directly under the font, saving valuable spance behind the bar.

- Has over 4 times more cooling surface area per ml of product than a standard heat exchanger.

- Dispensed drinks temperatures can be within 1ºC – 2ºC of the python recirculation temperature.

- Stable dispenser temperatures due to the low volume of product within the CoolTube and its unique heat exchange technology. Thus removing any dwell pint issues.

- Scope to include the technology inside the post of dispense.

- CoolTube has over 4 times more cooling surface area per ml of product than a standard pod and holds less than 80% of the amount of coolant. For example, the surface area cooling of the beer coils in the CoolTube is 24cm² per ml of beer. This compares to other heat exchanger products which have less than 6cm² per ml of beer surface area cooling.