Craft Beer Line Cleaning System Offer

Dispense Great Beer.

Cleaning beer lines without corrosive chemicals has never been easier (or affordable).

BRACTON DOSATRON AUTOMATIC

BEER LINE CLEANING SYSTEM

Bracton, the most trusted name in beer hygiene now offers the best in class beer line dosing cleaning system on a rental basis for less than $10 per week. Save time, reduces wastage and best of all uses Bracton’s award winning non hazardous Craft beer line cleaning detergent, click below to apply.

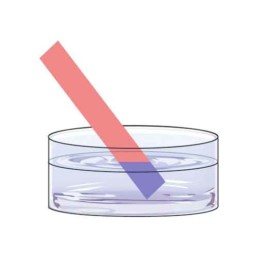

The Bracton Craft Beer Line Mixing System is the industry standard in safety and efficiency in beer line cleaning. When connected to water supply, the dispenser operates without electricity, using water pressure as the power source. As water flows through, it activates the dispenser drawing the correct mixture of Craft Beer cleaning solution (accurate to 0.1%) into the beer lines and towards the beer taps.

The Bracton Craft Beer Line Mixing System increases efficiency by mixing the correct amount of cleaning solution (no wastage) and reducing labour requirements (no setup time). This enhances safety precautions by eliminating a staff contact point with chemicals and pressurised vessels.

INCREASED EFFICIENCY

- Solution is prepared instantaneously NEW

- Dose of concentrate is proportional to water flow

- Dose remains precise

ENHANCED SAFETY

- CO2 can be eliminated during the cleaning process > No electricity, reduced risk

- No direct contact with concentrate

- Environmentally friendly, limiting risk of pollution

SIMPLE AND EFFECTIVE

- Easily fits in cellars and cool rooms

- Wall mounted

- Easy to use and adjust

- Reduced labour cost

OPTIONAL AND ADDITIONAL ACCESSORIES

- Safety Kit

- MSDS / SDS Kits

- On-site Service and training courses

- Cleaning Logbook

- Mobile Trolley

Bracton Craft Beer Non Hazardous Mixing System

Suitable for use with Bracton Craft Beerline Cleaner

BRACTONSAFE CRAFT BEER LINE CLEANER (Non-Hazardous)

Brewery approved BractonSafe Craft Beer Line Cleaner is formulated using the latest in surface active technology.

This product is non-hazardous making the workplace safer and eliminating the need for storage of caustics.

BractonSafe Craft Beer Line Cleaner has proven to deliver improved head retention and beer presentation leading to increased beer sales.

BSSAFESET3 Full Safety Kit

- non-vented goggles

- gloves

- mask

- apron

- test strips

- signage

BSAFESET2

Full safety kit excluding apron.

BSAFESET

Non-vented goggles and gloves.

BEER LINE CLEANING SAFETY EQUIPMENT

Meet your health and safety requirements with a Bracton Personal Protective Equipment (PPE) Safety Kit containing suitable PVC gloves and goggles for manual handling of any hazardous chemicals.

BSSAFESET3 Full Safety Kit

- non-vented goggles

- gloves

- mask

- apron

- test strips

- signage

BSAFESET2

Full safety kit excluding apron.

BSAFESET

Non-vented goggles and gloves.

Bracton Safe

Craft beer line cleaner and glass care brochures

https://www.youtube.com/watch?v=Q86QRpQ7LOc&app=desktop

https://vimeo.com/217780953#t=168s

Note: Bracton section starts at 2 minutes 48 seconds.

Beer & Wine Glasscare

Beer + Wine Glasscare

For both packaged and keg beers, no item of dispensing equipment is more important than the beer glass. All the good work in having an excellent cellar operation and regular beer line clean can be completely undone with poorly maintained glassware. A dirty glass seriously impair beverage presentation, flavour, clarity and head of the beer. In particular, the thick creamy, last head on the beer that customers love can be spoiled by even the slightest residue of grease / food fats on the glass. The easiest solution for perfect glasses is the regular and correct use of brewery approved Bracton glass care products.

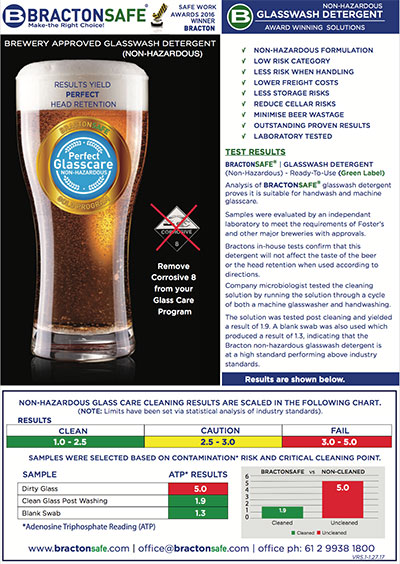

BRACTON GLASSWASH

Glasses when washed between drinks must use a glasswash detergent to remove deposits left on the surface from use to maintain hygiene and beverage quality.

Brewery approved BractonSafe Glasswash eliminates the need for drying agents such as rinse aids. BractonSafe Glasswash is the preferred detergent as it has the ability to hygienically clean, lifting stains from the glass and also be the ONLY brewery approved non-hazardous glass washing detergent available. BractonSafe Glass Wash delivers cleaner glasses and polycarbonate eliminating many of the common WH&S issues for bar staff, by using a non-corrosive product.

Using BractonSafe Glasswash detergent in your glasswasher helps beer hold its head for longer in the glass. No wonder it is Australia’s favourite everyday glasswash detergent.

NOTE: To ensure perfect beverage presentation, beverage glasses should be washed with hot water with a glass wash detergent specifically designed for beverage glasses and rinsed at 82C for a minimum of 10 seconds.

Fortunately many glass washing machines will automatically ensure the temperature is correct, so all you have to do is ensure a quality beverage glasswashing detergent is used. BractonSafe Glass Wash detergent is suitable for use with all makes and models of commercial glass washing machines and will assist in delivering beverages with perfect presentation

Available in two formulations;

- Economical concentrate (BLUE)

- Ready to use (GREEN) glasswasher ready.

NOTE: SAFE FOR USE ON GLASS & POLYCARBONATE.

Product Data Sheet – Glasswash Detergent – Concentrate (Blue Label)

Product Data Sheet – Glasswash Detergent – Ready To Use (Green Label)

BRACTONSAFE GLASSWASH Ready To Use (GREEN LABEL)

3 x 5L Carton

25L Drum

BRACTONSAFE GLASSWASH CONCENTRATE (BLUE LABEL)

3 x 5L Carton

25L Drum

BRACTON PINK SOAK POWDER

REMOVES GLASS HAZE

USE WEEKLY

Cloudy / Chalky looking glasses? Lipstick?

Not a problem. Bracton Pink Soaking Powder removes the heaviest stains with ease. We recommend that beverage glasses have a deep clean every week to ensure perfect glasses. There are number of methods to perform deep clean on glasses, If you have a Bracton Commercial Glasswasher your in luck! We have built a soak cycle function into the machine, press Soak on your machine add 2/3 scoop of Bracton Pink and a couple of minutes later, new glasses!

Over time glasses develop a cloudy hard scale build-up on the glass interior, requiring the need for a deep clean. Brewery approved Bracton Pink Glass Soaker / Sanitiser simplifies the task of destaining all glassware, china, plastics and cutlery ensuring sparkling hygienic results every time!

MANUAL CLEANING – Soak glasses in trays in this solution for 5 to 10 minutes then simply run through your glasswasher.

MACHINE CLEANING – Bracton Glasswashing Machines have an inbuilt soak function to eliminate this labourous task. Add half to two thirds of a scoop (every 5 racks) of Bracton Pink to the machine wash bay of a Bracton MR, BR or BR2 Series glasswasher, set the machine to soak cycle and press start. NOTE: Polycarbonate Glass safe.

BRACTON PINK SOAKER

5Kg

10Kg Pail

Beer line cleaners

Beerline Cleaners

Bracton beer line cleaners are used in 7 out of 10 hotels across Australia. Approved by all major and local breweries in Australia, Europe and USA.

Weekly beer line cleaning is part of the essential process for fresh and crisp tasting beer. When used correctly, Bracton Beerline Cleaners ensure a total clean, meaning all beer stone and bacteria build-up is completely removed from beer lines, FOB detectors, beverage heat exchangers and font riser lines. Bracton Beerline Cleaners are approved and often recommended by major brewery technicians to guarantee the beer tastes as it should, so you can serve the best possible beer.

The four key components to the beer line cleaning process that determine the level of hygiene achieved as specified by the major breweries:

- Chemical Contact Time with Beer Lines – Laboratory research indicates beerline cleaning should be conducted for a minimum of two hours. deviation from this minimum contact time, may cause inconsistent results.

- Frequency of Beer Line Cleans – Beer lines should be carried out once a week to ensure clean beer lines, this is paramount for warmer regions.

- Chemical Used – There are a variety of beer line cleaners on the market, for best results every time we recommend the use of Bracton DP1 & DP2 two part beerline cleaner. The Bracton DP1 & DP2 two part beer line cleaning process has consistently outperformed the alternatives for over thirty five years, majority of Australian Hotels & Clubs cannot be wrong! Bracton DP2 provides superior bacteria kill rate and sanitation over single part cleaners. In areas where a single part beerline cleaner is preferred use Bracton Twin.

NOTE: Both Bracton beerline cleaning processes are brewery approved for weekly cleaning and it is unnecessary to switch between beerline cleaners, for more information contact Bracton or your local draught beer technician. - Type of beer – Each type of beer is formulated differently and therefore some beers cause greater build up in beer lines than others. A weekly beer line clean ensures consistency across all beer types.

BRACTONSAFE CRAFT BEER LINE CLEANER (Non-Hazardous)

Brewery approved BractonSafe Craft Beer Line Cleaner is formulated using the latest in surface active technology.

This product is non-hazardous making the workplace safer and eliminating the need for storage of caustics.

BractonSafe Craft Beer Line Cleaner has proven to deliver improved head retention and beer presentation leading to increased beer sales.

BSSAFESET3 Full Safety Kit

- non-vented goggles

- gloves

- mask

- apron

- test strips

- signage

BSAFESET2

Full safety kit excluding apron.

BSAFESET

Non-vented goggles and gloves.

DP1 / DP2 DETERGENT

TWO PART BEER LINE CLEANERS

Bracton DP1 & DP2 Brewery Approved Beerline Cleaner is Australian Hotel & Clubs preferred beer line cleaner.

Available in a range of sizes to suit your venue. Bracton DP1 & DP2 can be used for beer line recovery cleans, contact your draught beer technician or Bracton for more information on performing a line recovery clean.

Product Data Sheet – Bracton DP1 Beer Line Cleaner

Product Data Sheet – Bracton DP2 Beer Line Cleaner

Bracton DP1 Beer Line Cleaners

3x5L Carton

15L Drum

24L Drum

Bracton DP2 Beer Line Cleaners

3x5L Carton

15L Drum

24L Drum

Bracton DP1 & DP2 Kits

10L Set (2 x 5L)

10L Handypack Set (10 x 1L)

20L Set (4 x 5L)

TWIN DETERGENT

ONE PART BEER LINE CLEANER

Bracton Twin Brewery Approved Single Part Beerline Cleaner suitable for use in colder regions with low levels of beer line build up.

Bracton Twin

10L Set (10x1L)

15L Drum

BRACTON DOSATRON AUTOMATIC

BEER LINE CLEANING SYSTEM

The Bracton Beer Line Mixing System is the industry standard in safety and efficiency in beer line cleaning. When connected to water supply, the dispenser operates without electricity, using water pressure as the power source. As water flows through, it activates the dispenser drawing the correct mixture of DP1 and DP2 cleaning solution (accurate to 0.1%) into the beer lines and towards the beer taps.

The Bracton Beer Line Mixing System increases efficiency by mixing the correct amount of cleaning solution (no wastage) and reducing labour requirements (no setup time). This enhances safety precautions by eliminating a staff contact point with chemicals and pressurised vessels.

Bracton Dual Mixing System

Suitable for use with Bracton DP1 & DP2 Beerline Cleaner

Bracton Single Mixing System

Suitable for use with Bracton TWIN Beerline Cleaner

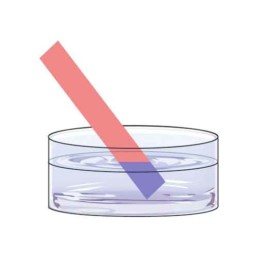

INDICATOR TEST PAPERS FOR BEER LINE CLEANERS

Bracton Test Papers – A simple method of testing when Beerline Cleaner is present. Paper turns blue in alkaline solutions, a must for safety.

USAGE: After performing normal brewery cleaning process and flushing, test for alkalinity by taking a pink test paper and wetting it with beerline flush water from tap. If it changes to a bluish colour, then continue flushing with water and retest until paper stays pink. Pink colour on the testing paper means it is safe to remove signs.

Bracton Test Papers

200 Strip Pack

BEER LINE CLEANING SAFETY EQUIPMENT

Meet your health and safety requirements with a Bracton Personal Protective Equipment (PPE) Safety Kit containing suitable PVC gloves and goggles for manual handling of any hazardous chemicals.

BSSAFESET3 Full Safety Kit

- non-vented goggles

- gloves

- mask

- apron

- test strips

- signage

BSAFESET2

Full safety kit excluding apron.

BSAFESET

Non-vented goggles and gloves.

Safety data

Safety Data

Safety Data Sheets (SDS) for Bracton Range

Bracton Craft Beerline Cleaner SDS

Bracton DP1 SDS

Bracton DP2 SDS

Bracton Twin SDS

Bracton Glasswash SDS

Bracton Glasswash RTU SDS

Bracton Pink Glass Soaker SDS

Bracton Taps & Fittings Soaker SDS

Bracton Long Life Glycol SDS

Bracton Keg Coupling Disinfectant SDS

Bracton Ice Machine Cleaner SDS

Bracton Stainless Polish SDS

Bracton Spray Away SDS

Bracton Rejuvenator SDS

Bracton Gas Leak Testing Solution SDS

Bracton Food Surface Sanitiser SDS

Bracton Vanilla Fresh SDS

Bracton Descaler SDS

Bracton Bubbles SDS

Bracton Cellar Guard SDS

Bracton Medi1 SDS

Bracton Virucidal Hand Gel 70% SDS

Bracton Hand Gel SDS

Bracton Hand Gel 80% SDS

Brewery chemical approvals

Bracton beer line cleaners & glass wash detergents have undergone rigorous testing by most major breweries around the world. Major Breweries unanimously agree that Bracton Beerline Cleaners deliver a total clean, meaning that when a venue is correctly cleaned with Bracton the beer will taste as it has designed to taste.

For more information on how to switch to Bracton where ever you are, contact your local supplier or call +61 2 9938 1800.

Australian Breweries

European Breweries

American Breweries

Distilled water - Ultra high grade

Distilled Water

BRACTON DISTILLED WATER

Bracton manufactures high quality distilled water by vapour recompression distillation process meaning we produce one of the highest grades of industrial and commercial distilled water in Australia. The Bracton distillation process removes minerals, salts, viruses, bacteria, cysts, heavy metals, radionuclides, organic’s, inorganic’s, and particulates leaving a pure product suitable for a range of industrial, commercial and residential applications.

- Pharmaceutical distilled water

- Distilled water for cleaning industries

- Supermarket distilled water

- Automotive distilled water

- Hardware distilled water

- Industrial distilled water

NOTE: Distilled water is demineralised, though demineralised water is not necessarily distilled.

Standard Packaging

3x5L Cartons

25L

200L

1000L

Palletised distilled water

72 x Cartons (3x5L)

32 x 25L Drums

4 x 200L Drum

1000L

Refill

IBC Refill options available, min refill order 200Lt.

Private / Custom Label : options available on request

Distilled water has many applications where a very high level of water purity is required. Below is a list of distilled waters key applications.

INDUSTRIAL DISTILLED WATER

- Mechanical Engineering & Motor Industries – Distilled water is preferable to tap water for use in automotive cooling systems. The minerals and ions typically found in tap water can be corrosive to internal engine components, and can cause a more rapid depletion of the anti-corrosion additives found in most antifreeze formulations.

- Wet cell battery servicing – Distilled water is also commonly used to top up lead acid batteries used in forklifts, cars and trucks. The presence of other impurities commonly found in tap water will significantly reduce battery lifespan.

- Laboratories Pharmaceutical companies

- Petrochemical and chemical

- Laser cutting

- Electronics manufacturing facilities

- Drilling rigs and marine desalination

COMMERCIAL DISTILLED WATER

- Heat Exchange Systems – ie Dilution of Propylene Glycol or Ethylene Glycol Systems.

- Auto Clave Sterilising by surgeries and laboratories – conductivity of 2 µs/cm and a TDS (total dissolved solids) 1.38 ppm.

- Photographic Labs

- Hospitals and Doctor’s Rooms

- Hair Salons – Chlorine free rinsing of hair

- Laundromat / Ironing – using distilled water in steam irons for pressing clothes can help reduce mineral build-up and make the iron last longer.

- Continuous Positive Airway Pressure (CPAP) machines

- Radiator coolants

- Dentistry

- School Science Laboratories

Technical

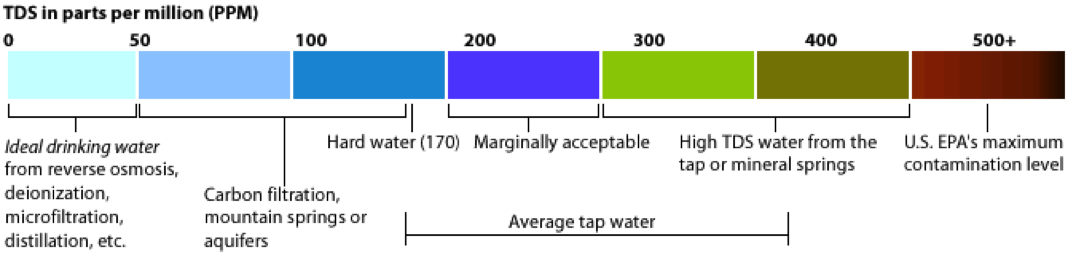

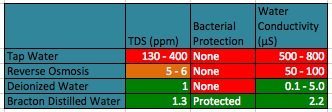

The effects of poor quality water often go unnoticed, however in many industrial and commercial applications, equipment life can be extended and unscheduled down time can be reduced by choosing higher quality water. Understanding the importance of water quality is critical.

Which quality of water is right for your application?

Total Dissolved Solids (TDS) are the total amount of mobile charged ions, including metals minerals or salts dissolved water, generally expressed in units of mg per unit volume of water (mg/L), also referred to as parts per million (ppm).

Total Dissolved Solids (TDS) are the total amount of mobile charged ions, including metals minerals or salts dissolved water, generally expressed in units of mg per unit volume of water (mg/L), also referred to as parts per million (ppm).

In general, the lower the Total Dissolved Solids concentration the better for industrial and commercial applications. Distilled water has virtually zero conductivity. Conductivity is usually about 100 times the total cations or anions expressed as equivalents. TDS is calculated by converting the EC by a factor of 0.5 to 1.0 times the EC, depending upon the levels. Typically, the higher the level of EC, the higher the conversion factor to determine the TDS. NOTE – While a TDS meter is based on conductivity, TDS and conductivity are not the same.

Why use distilled water over reverse osmosis?

Technical advances, in the Bracton distillation system, allow production of distilled water to ≤ 1 ppm total dissolved solids (TDS). The Bracton water distillation process consistently removes about 99.9% of the contaminants, while the best reverse osmosis systems start at about 98%, then rapidly degrades pending the type installed reverse osmosis (RO) system.

The small pores in the membrane of reverse osmosis systems block particles of large molecular structure like salt, though more dangerous chemicals like pesticides, herbicides, and chlorine are molecularly smaller than water, thus are not cleaned from water produced by reverse osmosis.

Contrastingly distillation, more specifically vapour recompression distillation, will remove any chemicals or organic materials with higher boiling points than water. Such chemicals and organic materials with higher boiling points include minerals*, trace amounts of metals, many volatile organic chemicals (VOCs), and nitrate.

The process of distillation kills and removes virtually all bacteria, viruses and other organic and inorganic contaminants, making Bracton Distilled Water the ideal water for use in most industrial applications. Minerals include salt, manganese, iron, fluoride, lead, and calcium. heavy metals include lead, arsenic, and mercury.

Heat transfer fluids (Glycol)

Heat Transfer Fluids

Various industrial and commercial heat transfer systems operate at temperatures outside the normal freezing and boiling points (of water). In order to protect heat transfer systems from freezing, bursting or boiling, a propylene glycol water mixture is used in secondary loop systems. In the case of cooling systems the heat transfer fluid is used to reduce the freezing point below operational temperatures, whereas the heat transfer fluid is used to increase the boiling temperatures in alternative applications.

Bracton Long Life Heat Transfer Fluid

Not all Propylene Glycol is the same, BractonSafe Long Life Propylene Glycol is a specifically formulated heat transfer liquid with built in inhibitors to assist in the prevention of corrosion and fungus growth in heat transfer systems. BractonSafe Long Life Propylene Glycol is an odourless liquid, recognised as safe for use in food & industrial applications by the relevant US and Australian authorities. Bracton offers two types of Propylene Glycol; BractonSafe Long Life Heat Transfer Fluid and Standard USP Grade.

BRACTON LONG LIFE HEAT TRANSFER FLUID (USP GRADE PROPYLENE GLYCOL WITH INHIBITORS)

BractonSafe Long Life Propylene Glycol with Inhibitors is formulated with USP Grade PG and has five times the normal life span of standard USP Grade Propylene glycol. Bractons’ special formulation reduces wear on heat transfer systems, ensuring equipment remains hygienic and corrosion free for longer, protecting plant equipment against excessive wear. Bracton Long Life Glycol is manufactured with USP grade propylene glycol and FDA approved inhibitors.

The product has been in use in the hospitality and food processing industries for the past 15 years. Bracton Long Life Glycol as recent under gone testing at a NATA lab for the following to confirm anti-corrosive capabilities; ASTM D1384, ASTM D6130, ASTM D5827, ASTM D6130, ASTM D5827, OL1029, OL1034, ASTM D1287, OL1003 & ASTM D1121. Shelf life of sealed, unused Bracton Long Life Glycol is five years from date of manufacture. Monthly or quarterly checks of pH and concentration by refractive index are recommended, ask about our in-house analysis options.

BRACTON PROPYLENE GLYCOL USP STANDARD

BractonSafe propylene glycol USP is a high purity product, which meets the requirements of the current United States and European Pharmacopeias and various other regulations and standards for pharmaceutical, food and cosmetic additives. As a result of its low vapour pressure, low toxicity, low flammability and high purity, propylene gycol USP is cleared for use in the United States in accordance with U.S. FDA requirements. Bracton Glycol is cleared for indirect food contact: 21 CFR 175.105, 21 CFR 175.300, 21 CFR 175.320, 21 CFR 176.170, 21 CFR 176.210, 21 CFR 177.1680, 40 CFR 180.1001(c) (e) & 40 CFR 182.99.

BractonSafe Long Life Heat Transfer Fluid is also known as;

- BractonSafe Propylene Glycol with Inhibitors

- Inhibited Propylene Glycol

- PG with Inhibitor – PGUSP

- Long Life Propylene Glycol

- Secondary heat transfer fluid BractonSafe Long Life Propylene Glycol is a economical alternative to Dow’s Dowfrost(TM) Product Line.

NOTE: BractonSafe can supply bulk ethylene glycol and technical grade propylene glycol on request, these products are not suitable for direct or indirect food applications.

BractonSafe Long Life Propylene Glycol with corrosion protection

3 x 5 Kg Carton

25 Kg Drum

215 Kg Drum

1000 Kg IBC (Tote)

Nb: BractonSafe Long Life Propylene Glycol with corrosion protection is also available in pre diluted, ready to use concentrations. Ideal for new installations.

BractonSafe Propylene Glycol USP Grade Standard

215 Kg Drum

1000 Kg IBC (Tote)

Bracton Preservative (Glycol Corrosion Inhibitor)

12x500mL Carton

3 x 5L Carton

25L Drum

215L Drum

Bracton Distilled Water

25L Drum

215LDrum

1000L IBC (Tote)

TECHNICAL GUIDANCE

Can standard Propylene Glycol be Inhibited or converted to Long Life Glycol?

Yes, with BRACTON PROPYLENE GLYCOL PRESERVATIVE (GLYCOL CORROSION INHIBITOR)

Propylene Glycol is an excellent heat transfer liquid with low toxicity, suitable for food grade applications such as beverage cooling and food processing. One drawback is that Propylene Glycol has an average shelf life of twelve months from date of manufacture, when stored in accordance with PG manufacturers guidelines (below 40C and away from UV light sources).

Given that Propylene Glycol is for the most part imported into Australia, the actual shelf life is closer to 8 – 10 months by the time glycol enters into operation. As Propylene Glycol is exposed to operational environments including elevated temperatures and oxidisation, Propylene Glycol fluid reacts becoming acidic, in turn increasing the wear on equipment and higher maintenance costs. Fortunately, The chemists at Bracton have developed an easy to use food grade additive, designed to preserve the shelf life of USP grade propylene glycol by up to five times in normal conditions.

Bracton Propylene Glycol Preservative is made with food grade FDA approved materials and has been employed to protect food processing systems of some the worlds largest multi-national food manufacturers, breweries, hotels and industrial manufacturers. Bracton Propylene Glycol Preservative serves as the front line defence, protecting against systems against acidity, corrosion while inhibiting mould and fungus growth.By choosing to use Bracton Propylene Glycol Preservative in heat transfer applications, your company will save in replacement and maintenance costs.

Ideal for use:

- Commercial & Domestic Draught Beer Systems

- Food Processing systems

- Dairy, Seafood and Wine production systems

- Any commercial or industrial system that requires glycol use.

Bracton Propylene Glycol Preservative Characteristics:

- Prevents corrosion

- Prevents bacterial build up

- Prevents circulation blockage

- Extends the life of Propylene Glycol

- Increases efficiency in systems

Use: Bracton Propylene Glycol Preservative 10Lt treats 200Kg of pure propylene glycol (UNDILUTED).

NOTE: Bracton Propylene Glycol Preservative is also known as Propylene Glycol Inhibitor.

Where can Propylene Glycol be used?

- Propylene Glycol Applications Coolant, anti freeze, heat transfer, thermal transfer in secondary heat transfer systems.

- Beverage and beer cooling systems

- As a less toxic antifreeze in solar water heating systems

- To regulate humidity.

Why should ethylene glycol not be used in food applications?

Risks – Because secondary refrigerant is pumped around a beer system with flooded fonts, there is a slight chance there may be cross contamination. Therefore the refrigerant MUST be non-toxic.

Toxicity – Ethylene glycol poisoning is caused by the ingestion of ethylene glycol (the primary ingredient in both automotive antifreeze and hydraulic brake fluid). It is a toxic, colourless, odourless, almost non-volatile liquid with a sweet taste and is occasionally consumed by children for its sweetness. Following ingestion the symptoms of poisoning follow a three-step progression starting with intoxication and vomiting, before causing metabolic acidosis, cardiovascular dysfunction, and finally acute kidney failure. The major cause of toxicity is not the ethylene glycol itself but its metabolites. Propylene Glycol The acute oral toxicity of propylene glycol is very low, and large quantities are required to cause perceptible health damage in humans.

Identification:

a. Raw Ethylene Glycol –Can be colourless or fluorescent green depending on supplier

b. Raw Propylene Glycol – Colourless

c. BractonSafe Long Life Propylene Glycol – Translucent Pink

What does freeze & burst protection mean?

Freeze protection is necessary if a cooling system is going to be actively pumping fluid at the lowest operational temperature where there is no room in the system for expansion to accommodate a slush formation. To obtain adequate freeze protection, the glycol solution must maintain a freezing point at least 3 degrees Celsius lower than operational temperature. Frequent scheduled system checks are recommended to ensure the propylene glycol water mixture is not diluted beyond the required operational ratios.

Burst protection is required if the system will sit dormant at temperatures below the freezing point of the fluid and there is adequate space to accommodate the expansion of the ice/slush mixture while the system is inactive. For these situations, the system needs enough glycol to keep the fluid from freezing solid. As the temperature drops below the freezing point, ice crystals begin to form. Because water in the solution freezes first, the remaining glycol solution becomes concentrated. This results in a flowable slush of ice crystals and glycol.

Bracton manufactures a Long Life Propylene Glycol which has a low toxicity level and can be used in equipment that has contact with food and beverage products. Including beverage cooling, food processing, secondary cooling and heating agents, dehumidifying and defrosting.

Why use distilled water when diluting Heat Transfer Fluids?

Tap water quality varies significantly from location to location. The impurities and minerals found in tap water while general not harmful to one’s health, can be detrimental to heat transfer systems, increasing the risk of unscheduled system down time and reducing system life span. Hard water causes scale build up, where salts cause corrosion to systems. Therefore heat transfer fluids are preferably diluted with distilled or deionised water.

- Chlorides < 25ppm

- Sulfates < 25ppm

- Total hardness as Calcium Carbonate (CaCO3) < 100ppm

Definition: Hard water is water that has high mineral content. Hard water can pose serious problems in industrial and commercial equipment, where water hardness is monitored to avoid costly breakdowns in boilers, cooling equipment, and other equipment that handles water.

Analysis of water hardness in major Australian cities by the Australian Water Association [AWA] shows a range from very soft (Melbourne) to very hard (Adelaide). Average Reported Hardness levels of Calcium Carbonate (CaCO3) in ppm are:

- Canberra: 40

- Melbourne: 10 – 26

- Sydney: 39 – 60

- Perth: 29 – 226

- Brisbane: 100

- Adelaide: 134 – 148

- Hobart: 6 – 34

- Darwin: 31

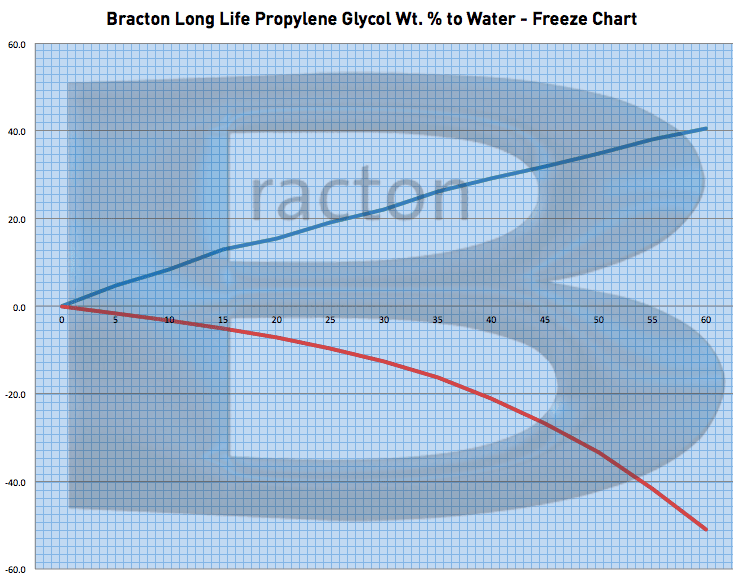

Propylene Glycol dilution guidance

- Identify equipment operational temperature range.

- Read graph to identify desired Bracton Propylene Glycol mixing ratio.

- To a clean head transfer system add the right amount of Bracton Propylene Glycol.

- Top up with distilled or deionised water and agitate water.

- Check solution concentration with a refractometer to ensure desired operating parameters.

NOTE: Bracton recommends a minimum dilution 25% to maintain system corrosion and fungus protection.

Can Bracton analyse our heat transfer fluid?

Yes, contact your local Bracton distributor today and ask for a Bracton heat transfer fluid check kit. Bracton will analyse the sample and provide a report and recommendation to ensure your fluid is operating to specification.

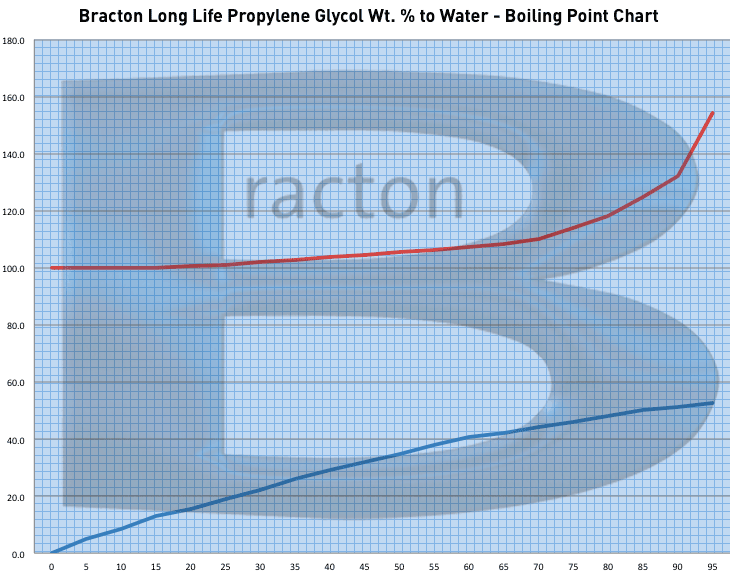

How much water should be added to reach the correct freeze or boiling point?

RED LINE: Relative Freeze Point°C

BLUE LINE: Relative Refractometer Reading °Bx

CENTRE LINE : Propylene Glycol Concentration

RED LINE: Relative Boiling Point°C

BLUE LINE: Relative Refractometer Reading °Bx

CENTRE LINE : Propylene Glycol Concentration

Cellar area

Cellar Area

Bracton manufactures a complete range of specialist chemicals for use in cellars, including beer line cleaners, coolants, floor cleaners, mould removers and gas leak detection fluids.

PROPYLENE GLYCOL BEVERAGE COOLING

Not all Propylene Glycol is the same. By using Bracton Long Life Propylene Glycol at the correct ratio, your venue is taking preventative maintenance action to protect against:

- Corrosion within glycol storage tanks

- Microbial growth reducing or blocking flow rates (Jelly formation)

- Unscheduled down time – i.e. system freezing

- Wear on equipment through increased loads on glycol pumps

- Increased electricity consumption

LONG LIFE HEAT TRANSFER FLUID PROPYLENE GLYCOL WITH INHIBITORS

Bracton USP Grade Long Life Glycol with FDA approved preservative and corrosion control has five times the life span of standard USP Grade Propylene glycol. Bractons’ special formulation ensures your system remains hygienic and corrosion free for longer. Ideal for food

Suitable for use in beverage cooling systems, food processing, laser systems, wineries, engineering and other heat transfer applications.

Bracton USP Grade Long Life Propylene Glycol

3 x 5Kg Carton

25Kg Drum

215Kg

1000Kg IBC

BRACTON GLYCOL PRESERVATIVE – FOOD APPLICATIONS

Propylene Glycol is an excellent heat transfer liquid with low toxicity, suitable for food grade applications such as beverage cooling and food processing. One drawback is that Propylene Glycol has an average shelf life of twelve months from date of manufacture, when stored in accordance with PG manufacturers guidelines (below 40C and away from UV light sources). Given that Propylene Glycol is for the most part imported into Australia, the actual shelf life is closer to 8 – 10 months by the time glycol enters into operation. As Propylene Glycol is exposed to operational environments including elevated temperatures and oxidisation, Propylene Glycol fluid reacts becoming acidic, in turn increasing the wear on equipment and higher maintenance costs.

Bracton have developed an easy to use food grade additive, designed to preserve the shelf life of USP grade propylene glycol by up to five times in normal conditions. Bracton Propylene Glycol Preservative is made with food grade FDA approved materials and has been employed to protect food processing systems of some the worlds largest multi-national food manufacturers, breweries, hotels and industrial manufacturers. Bracton Propylene Glycol Preservative serves as the front line defense, protecting against systems against acidity, corrosion while inhibiting mould and fungus growth.

By choosing to use Bracton Propylene Glycol Preservative in heat transfer applications, your company will save in replacement and maintenance costs.

Ideal for use on:

• Commercial & Domestic Draught Beer Systems

• Food Processing systems

• Dairy, Seafood and Wine production systems

• Any commercial or industrial system that requires glycol use.

Characteristics:

• Prevents corrosion

• Prevents bacterial build up

• Prevents circulation blockage

• Extends the life of Propylene Glycol

• Increases efficiency in systems

Use: Bracton Propylene Glycol Preservative 10Lt treats 200Kg of pure propylene glycol (UNDILUTED).

Bracton Glycol Preservative

12 x 500mL

3 x 5L carton

25L drum

200L drum

1000L tote

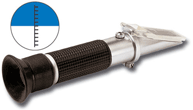

GLYCOL CONCENTRATION REFRACTOMETER

Glycol / water concentration should be tested on a weekly basis to prevent line freezing. This can be done quickly with the Bracton Refractometer and dilution chart. It is important to get the propylene glycol / water concentration correct, too low of a glycol concentration will increase the risk of freezing the system, too high of a glycol concentration will cause additional load placed on the glycol pumping system increasing electricity and maintenance costs.

The Bracton Glycol Refractometer is:

- Easy to use

- High quality, accurate testing result

- Automatic Temperature Compensation (ATC)‚ (accurate analysis in all temperatures)

BRACTON INTERNAL FONT CLEANER

In the event of a blockage in the cooling system lines, beverage heat exchanger or fonts, the system can be flushed with Bracton Font Cleaner. Font Cleaner can be re-circulated through the system will break down the jelly which was formed through a reaction between the acidity of the previous glycol solution and metals in the system. Consult your beer technician or Bracton direct for more information.

BRACTON FONT CLEANER

10L Kit

BRACTONSAFE SPRAY AWAY – BAR AREA & CELLAR CLEANER

Spray Away is a concentrated surface cleaner suitable for use in food areas. Bracton Spray Away is a unique product that replaces many hazardous chemicals in the work place. Most products usually require high pH levels (alkaline detergents) to emulsify oil and grease, but Spray Away will do the job in half the time, with less effort. This ability to remove dirt, grease and oil with out a high pH level is not only safe for the user but also less damaging on assets and equipment.

- Economical – 25L makes 150 to 275L of cleaning solution

- Removes dirt, grease, grime, mould and mould spores

- Removes bar fly breeding areas

- Can be sprayed or used in a mop & bucket

- No odour (perfumed version available on request)

- Non hazardous + non toxic

- Biodegradable

- AQIS Approved

- Replaces over 20 commonly used cleaners

Spray Away has already been specified by some of Australia’s leading hospitality groups, delivering a significant reduction in the quantity of chemicals required to be stored in the workplace.

Simply apply the diluted Spray Away solution to the surface with a brush or mop and rinse. Spray Away, Surface Active Technology provides a total clean limiting future regrowth, keeping the bar area free from putrid odours for longer. Formulated to rapidly remove surface contaminates such as dirt, grease, grime, mould, bathroom scum and other stains from surfaces.

BRACTONSAFE SANITISER SPRAY

When the keg is dispatched from the brewery, bacteria can grow in between the keg seal and tamper cap. Prior to tapping a keg of beer or connecting any transfer / drop leads, a quick spray with food-safe odourless Bracton Food Safe Anti Bacterial Spray (Keg Coupling) Ready-To-Use Spray (Stock Code: BK002) will leave a thin bactericidal film, ensuring bacteria free connections every time. Available in ready to use spray bottles or concentrated dilutable disinfecting packs. Food Grade. AQIS Approved.

Product Data Sheet – Bracton Keg Coupling Disinfecting – Concentrate

Product Data Sheet – Bracton Sanitiser-Food Grade Concentrate

Bracton Sanitiser-Food Grade RTU Spray (RTU)

4 x 1L packed with sprayers

Bracton Sanitiser-Food Grade Concentrate

12 x 500mL concentrate cartons

BRACTON TAPS, PARTS + FITTINGS SOAKER + CLEANER

Breweries recommend keg couplers, beer taps and other beer fittings should be disassembled and soaked once a fortnight, this is ideally done during the soaking time of beer line cleaning process to minimise any down time. Immerse fittings into 10 Litres of water and add 500mL of Bracton Taps & Fittings Soaker (Stock Code: BTF002) for up to 20 minutes to remove beer stone, mould, fungus and any surface corrosion build-up. Rinse & Brush fittings under water after soaking and apply Bracton Anti Bacterial Keg Coupling Spray to sanitise.

Bracton Taps + Fittings Soaker

3 x 5L Carton

BRACTON TEST PAPERS

A strip of test papers for convenient and simple method of testing when Beerline Cleaner is present. Turns blue in alkaline solutions. A must for safety. USAGE: After performing normal brewery cleaning process and flushing, test for alkalinity by taking a pink test paper and wetting it with beerline flush water from tap. If it changes to a bluish colour, then continue flushing with water, retest till paper stays pink. Pink colour on testing means it is safe to remove signs.

Bracton Test Papers

200 Strip Pack

BRACTON PPE SET

Meet your occupational health and safety requirements with a Bracton PPE set containing suitable PVC gloves and goggles for manual handling of any hazardous chemicals.

DRUM TROLLEY

Reduce OH&S issues with Bracton stainless steel drum trolleys, ideal to reduce unnecessary lifting while keeping 15, 20 & 25Lt drums off the floor.

DRUM SPANNER

Open 15, 20 & 25Lt drums quickly and easily with a universal drum spanner.

BRACTONSAFE GAS LEAK TESTING SOLUTION

Simple, efficient and accurate, BractonSafe Gas Leak Testing Solution is designed to make gas supply leak testing quick and easy. Simply spray and watch for bubbles to identify leaks. Specifically formulated to prevent bacteria, mould growth & corrosion. Ideal to be used in conjunction with the Australian Standards / Bracton AS 5034 Logbook.

Bar area

Bar Area

Keeping the service area behind the bar clean and hygienic can be a challenge. Bracton has developed a couple of economical, multi use products to keep cleaning inventories down and surfaces clean. Manage odours, mould, bar flies and hygiene with Bracton.

BRACTON DESCALER GLASSWASHER CLEANER & DEODOURISING FLUID

Smelly Glasswasher or Dishwasher? Chalky / scale or unknown residues in glasswasher wash bay? Add a cup of Bracton Descaler to the wash bay of your recirculating glass washer and run the machine through a couple of cycles. Best of all, by using Bracton Descaler you are actively reducing the chance of unscheduled machine down time and improving the machine performance as Bracton Descaler cleans the internal pipes clear of organic build up.

Make Bracton Descaler part of your preventative maintenance programs. All commercial glass and dish washing equipment needs to be descaled on a regular basis to protect against scale build-up, nasty odours caused by bacteria and moulds, and to remove surface corrosion.

Bracton Descaler is the only descaler that can be added directly to re-circulating glass washers during weekly during normal washing cycles. May also be used to clean standard non re-circulating glass washing machine with gloves, goggles and scourer.

Product Data Sheet – Bracton Descaler

(suitable for commercial glasswashers & dishwashers)

BD002 3 x 5L Carton

BD003 25L Drum

BRACTON ICE MACHINE HYGIENE & CLEANER

Dirty ice machines produce dirty ice, negatively impacting on the hygiene and taste of the beverage. Ultimately, poor quality ice in beverages will affect the health of the consumer and sales of spirit based mixers and cocktail sales. The two aspects of ice machines that should be maintained are the filter(s), and ice storage bins. It is recommended that ice machines be cleaned every six months to maintain adequate hygiene eliminating scale deposits, mould and fungus.

To clean ice machines it maybe necessary to consult the machines manual to locate the cleaning or recirculating mode switch and method statement. For a complete clean add one litre of Bracton Ice Machine Cleaner to every thirty litres of water in the system for recirculation. After the cleaning process is finished, rinse the machine other thoroughly to ensure no debris or chemical is left; an acid litmus test would be ideal.

BIM002 3 x 5L Carton

BIM003 25L Drum

BRACTONSAFE REJUVENATOR – RESIDUAL BAR FLY & MOULD PREVENTION

Behind the bar can be the smelliest area in any hotel or club. These areas are commonly used as storage areas for beverage glasses and if left uncleaned are a breeding ground for mould, bacteria and bar flies increasing the risk of glass contamination leading to poor beverage presentation.

By keeping this area clean and hygienic with BractonSafe Spray Away and following up with a simple spray and wipe of BractonSafe Rejuvenator, you remove the habitat which bar flies require to breed. One clean with BractonSafe Rejuvenator will last up to 30 days.

Removing the impracticalities of weekly cleaning under-bar areas to remove the mould and bacteria from the underside of the bar and beer pythons.

Note: Rejuvenator is an oil and therefore should not be applied to floors or stairs where people walk. Rejuvenator is not for use on beer fittings that come into direct contact with the beverage (glasses, beer taps etc..).

BractonSafe Rejuvenator kills pungent odours and lengthens the period between cleaning cycles.

BR6750 6 x 750mL Carton

PROFESSIONAL ODOUR NEUTRALISING BRACTONSAFE VANILLA FRESH

For general purpose daily odour neutralising in bar, toilets and front of house areas most venues use an odour masking air freshener, however air fresheners only temporarily mask the odour or are formulated to block sense of smell.

Bracton has taken a different approach with Vanilla Fresh, developing a commercial grade disinfectant, based off AQIS formulation that kills bacteria and mould and encapsulates odours at the source, working in areas where traditional deodorisers do not work. BractonSafe Vanilla Fresh is the most effective odour remover from indoor areas such as toilet areas to remover urine smells, garbage areas carpets, tiles, rubber mats, fridge, cars and more.

Vanilla Fresh is ideal for the cleaning of commercial fridges, fridge seals and freezers.

BVF12750 12x750mL Spray Packs

BVF004 3 x 5L Carton

BVF002 25L Drum

BRACTONSAFE STAINLESS STEEL POLISH

There are some trade secrets to achieving a showroom finish on brushed and mirror finish stainless steel surfaces.

With the right equipment and application method your stainless steel surfaces can achieve a flawless finish with minimal effort. The key mistake made when cleaning stainless steel is that the user applies too much product or selects the wrong product for the task.

Spray a light coat of BractonSafe Stainless Steel Polish on to the surface or apply the volume equivalent of 10 cent piece to a lint free white rag and rub onto the surface, this will leave the surface spotless! In the event the stainless has tealeaf rust stains or surface corrosion, use SoSafe Metal Bright to remove these heavy stains.

BSSP12750 12x750mL Spray Packs

BSSP007 3 x 5L Carton

B 25L Drum

STAINLESS TEA LEAF STAIN REMOVER

SOSAFE METAL BRIGHT

Removes surface rust and rust stains with ease! Ideal to clean surface rust from stainless steel, chrome and alloys. Removes rust stains from most surfaces including tiles, bath-tubs and bbqs.

SoSafe Metal Bright has been specially formulated to remove surface rust, rust‚ tea-leaf‚ stains and other rust stains from a multitude of hard surfaces. Metal Bright pacifies the surface leaving a rejuvenated finish in as-new condition.

12x750mL Spray Packs

3 x 5L Carton

25L Drum

SPRAY AWAY BAR, CELLAR AND FRONT OF HOUSE CLEANER

BractonSafe Spray Away is a unique product that replaces many hazardous chemicals in the work place. The unique ability of Spray Away to cut through the heaviest grease, oil and dirt whilst disinfecting a surface to hospital standards is unmatched. Many products usually require high pH levels (alkaline detergents) to emulsify oil and grease, Spray Away will do the job in half the time with less effort. This ability to remove dirt, grease and oil with out a high pH level is not only safe for the user but also less damaging on assets and equipment.

- Economical – 25Lt makes 150 to 275Lt of cleaning solution

- Removes dirt, grease, grime, mould and mould spores

- Removes bar fly breeding areas

- Can be sprayed or used in a mop and bucket

- No odour (perfumed version available on request)

- Non hazardous and non toxic

- Biodegradable

- Replaces over 20 commonly used cleaners

Simply apply the diluted Spray Away solution to the surface with a brush or mop and rinse. Spray Away, Surface Active Technology provides a total clean limiting future regrowth, keeping the bar area free from putrid odours for longer. Formulated to rapidly remove surface contaminates such as dirt, grease, grime, mould, bathroom scum and other stains from surfaces.

Spray Away for General Purpose Cleaning

- Fast acting Spray + Wipe replacement.

- Cellar and bar area cleaner.

- Pre-cleaner, prior to applying BractonSafe Rejuvenator.

- Suitable bleach replacement for bathroom cleaning.

- Made from 4 parts water : 1 part Spray Away Concentrate.

Spray Away for Windows & Glass

- Made from 10 parts water : 1 part Spray Away Concentrate.

Spray Away for Heavy Duty Cleaning

- Removes shoe scuff marks from walls.

- Removes stains from carpets.

- Made from 0 parts water : 1 part Spray Away Concentrate.

BRACTONSAFE Spray Away Concentrate

3 x 5L Carton

25L Drum

200L Drum

1000L IBC

BRACTONSAFE Spray Away Refillable Bottles

12 x 750mL Bottles (4 of each type, filled)

- 4 x Spray Away – General Purpose

- 4 x Spray Away – Window & Glass

- 4 x Spray Away – Heavy Duty

NOTE: Empty labeled bottles are available on request

BENCH SANITISER RTU

No rinse residual surface disinfectant. Bracton Bench Sanitiser Ready To Use should be used on kitchen bench tops and food preparation areas prior to and after the preparation of food items. Use for sanitising food service areas.

Safe for use in food areas. DAFF Approved. Non rinse required. Surface Active Technology.

BSRTU12x750 12x750mL Spray Packs